Appendix 4 Calculating the amount of ammonia and biofilter media for an aquaponic unit

This appendix provides detailed explanations on the optimal amount of filtration media required to convert the ammonia into nitrate from a given amount of fish feed. In addition to the information provided in Chapter 8 of the main text of this publication, it is important to introduce two new parameters in the equations: total ammonia nitrogen (TAN) produced by fish feed

conversion rate of ammonia to nitrate by bacteria

DETERMINING THE AMOUNT OF AMMONIA PRODUCED BY FEED

Ammonia is a by-product from the degradation of proteins. The amount of ammonia in the water depends on several factors, including the quantity/quality of proteins or amino acids in the feed, the digestibility, the fish species, the temperature, and the removal of fish wastes from the aquaponic system. On average, 30 percent of the proteins supplied by the diet are retained in the fishes' body. Therefore, 70 percent of the nitrogen is lost: 15 percent is not digested, and exits as solid waste (faeces) and uneaten feed, while the remaining 55 percent is excreted by the fish as ammonia or products easily degradable into ammonia. In addition to the wastes directly dissolved, it is worth noticing that about 60 percent of the solid waste produced is taken out from the system by means of clarifiers or settlers, which leaves about 6 percent of the solid waste to be degraded into ammonia in the water. Overall, about 61 percent of the nitrogen from the feed becomes ammonia and is subject to nitrification.

Take the example of 20 kg of fish eating 1 percent of their body weight per day (200 g of fish feed). From these 200 g of feed (32 percent protein), the amount of ammonia produced is approximately 7.5 grams. To achieve this result, first the amount of nitrogen is calculated based on the percentage of protein in the feed; and the amount of nitrogen contained in the protein (16 percent). Then, the amount of wasted nitrogen. is calculated: 61 percent of the nitrogen is wasted (6 percent as undigested/uneaten feed retained into the system; 55 percent excreted by fish). For each gram of wasted nitrogen, 1.2 g of ammonia is produced, according to standard chemistry methods (not included here). The following equation shows the process:

200 g feed X (32 g protein/ 100 g feed) х (16 g nitrogen/ 100 g protein) х (61 g wasted nitrogen/ 100 g total nitrogen) х (1.2g NH/ 1 g nitrogen)=7.5 g ammonia

DETERMINING THE AMOUNT OF BIOFILTER MEDIA NEEDED BY NITRIFYING BACTERIA

The ammonia removal rate by nitrifying bacteria is 0.2-2 g per square metre per day. The removal rate depends on the biofilter design, water load (amount of water flowing through the bacteria), temperatures (higher biological activity at > 20 °C), salinity, pH, oxygen as well as suspended solids from fish wastes. To simplify the complex calculations needed, a conservative rate is used: 0.57 g of ammonia is converted per square metre of surface area per day. Given a daily amount of feed of 200 g and the resulting production of 7.5 g of ammonia, it is necessary to provide bacteria with an. operating surface area of 13.3 m2, as shown in the following equation:

7.5 g ammonia X (1 m2/ 0.57 g ammonia) = 13.3 m2

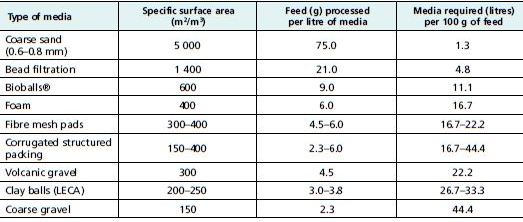

The surface for bacteria can be obtained from a wide choice of materials, each with a specific surface area (SSA), also known as the surface area to volume ratio, expressed as square metres per cubic metre (m2/m3). Common biofilter media include gravel, sand, fibre mesh pads and plastic filter medium. The SSA indicates the total surface that one cubic metre of a particular material would have if all its particles had their surface area measured. Some of these SSA values are recorded in Table A4.1 (see also Table 4.1). The volume of media required to convert the ammonia can be calculated using the SSA ratios. An example using volcanic tuff is provided in the following equation.

Volcanic tuff has an SSA of 300 m2/m3. The volume of tuff needed to guarantee an operating surface of 13.3 m2, calculated above, for nitrifying bacteria can be obtained with a simple division:

13.3 m2 x (1 m3 /300 m2) = 0.0443 m3

The final volume of tuff required to process 200 g of feed per day is 0.0443 m3. One cubic metre is equivalent to 1 000 litres, and therefore the volume of tuff required is 44.3 litres. Hence, 1 litre of tuff can convert the ammonia obtained by 4.5 g of feed.

(44.3 litres tuff / 200 g feed)/(1 litre tuff/ 4.5 g feed)

When using media bed aquaponic techniques, the amount of media used for plant growing far exceeds the minimum amount required for biofiltration and conversion of ammonia. This results in a robust system in the event of a severe reduction of the efficiency of the nitrifying bacteria. The system design described in Appendix 8 of this publication has a tuff volume of 900 litres, almost 20 times higher than the volume needed to process the ammonia produced from 200 g of feed.

TABLE A4.1

Specific surface area of selected biofilter media, including calculations of ammonia conversion of daily feeding, assuming 32 percent protein in feed

It is possible to use any biofilter medium and determine the volume needed by knowing the SSA. However, it is worth mentioning that the larger the SSA in the media is, the higher the risk of clogging if the water has some suspended solids, which can easily occur in overstocked aquaponic systems that are not adequately supplied with clarifiers or settlers to remove fish wastes.