Appendix 6 - Key considerations before setting up an aquaponic system

There are many fully functioning commercial and small-scale aquaponic units around the world. Aquaponic systems can be developed not only in tropical and subtropical regions, where favourable climatic conditions allow year-round production, but also in cooler areas of the world where winter seasons last up to six months. The question of running an aquaponic system in a specific place requires a comprehensive cost-benefit analysis that should assess its possible success upon certain economic, environmental, logistical/managerial and social conditions.

Many factors must be considered before embarking on an aquaponic project, whether it is for domestic production or more commercially focused. Many start-up aquaponic businesses have failed. A decision to create a commercial enterprise requires significant research, a business plan and a risk analysis. Such aspects are beyond the scope of this appendix. However, it does discuss below some of the key factors and requirements for operating any size aquaponic unit.

ECONOMIC FACTORS

One of the main factors that determine the possible success of aquaponics is its competitiveness against alternative production methods. The combination of both fish and plants doubles the risks of the investment that, in order to be profitable, must maximize both plant and fish production and revenues.

This implies that an analysis on the potential markets is an essential step towards the development of a business plan, as it should realistically find all the possible products, identify the profit margins and identify the key customers. A common mistake is to ask: "What can I produce?" instead of the more important questions: "What can I sell?", "To whom am I going to sell?", and only then "How am I going to produce it?"

Market analysis should identify the most profitable products and the most cost- effective management. This implies that the specific choice of fish can be significantly. different from the species generally used in aquaponics, mainly owing to market. demand and the costs of production.

In the decision-making process, there are substantial differences between a production focused for self-consumption and a market-oriented one. While the former can mostly. rely on retail prices to estimate the profit margins, the commercial-scale ventures have to find markets that might be closer to whole sale prices, especially in the case of large- scale operations. However, small-scale systems cannot benefit from economies of scale (e.g. a small greenhouse has a higher cost per square metre than does a larger one), which means non-commercial farmers may face higher production costs.

While aquaponics may, to some extent, be acknowledged as an "organic" production option in North America, this is not equally true in Europe where "organic" still applies only to soil-based production. The positive outlook derived from a more ecologically sound production can favour higher revenues in Western markets; however, this may not be equally possible in developing countries where customers' choices are. still primarily price-oriented. On the marketing side, an advantage could come from footprint labelling, as aquaponics appears to be the best aquaculture system in terms. of water conservation and a pollution-free solution that can support agriculture with consistent savings in fertilizers and chemical inputs. However, proper product development on this basis still needs to be done, providing also that aquaponics moves towards more energy-neutral management strategies.

One of the limits that still prevents aquaponics from fully expanding worldwide is that its investment costs are almost double those of standard hydroponic farming. However, this conviction is partly derived from the mistaken idea that aquaponics is a mere plant production system rather a recirculating aquaculture system (RAS) that additionally supports agriculture. If compared against a standard RAS, aquaponics shows consistent advantages in terms of capital and operating costs and for the degree of simplicity of the system. Greater success could be achieved if cost-saving designs/ projects were able to bring aquaponic setups closer to the investments costs of hydroponics. However, this would require more effort to focus on developing simpler

systems.

The possibility to set up aquaponics in unfavourable climates depends on the degree of investments needed for building greenhouses and running advanced climate control systems to maintain optimal water and air temperatures, humidity and ventilation. This would increase the initial and running costs, but at least, on this level, the investment costs for the greenhouse facilities may not differ significantly from those for hydroponics.

ENVIRONMENTAL FACTORS

There are some key considerations in determining where aquaponics is most applicable and beneficial. Regions in the world where soil fertility is poor (and particularly where replenishing the soil with nutrients via organic material is difficult and/or expensive) and water is scarce are the ideal locations. Aquaponics is competitive with even the most productive traditional aquaculture and agriculture sy stems in terms of water use. Aquaponic food production is extremely water efficient, as the vegetable growing methods are soil-less. However, to compete against hydroponics, fish-plant systems should be considered as a whole in order to justify higher installation costs. When taking these factors into consideration, semi-arid regions with poor access to water would stand to benefit the most from this new method of food production.

Water is a significant factor, especially for quality standards. Aquaponics has the great advantage of recirculating water, which avoids any need to procure large daily volumes to compensate for losses. In areas where water is muddy, contaminated by pollutants or pathogens/parasites, aquaponics, as well as RAS, is an ideal system to optimize fish production, reduce mortality of aquatic animals and improve quality. In this case, the extra investments needed to supply small volumes of good-quality water (e.g. through rain harvest or artesian wells) can be easily recovered by the added value from higher-quality fish and lower mortality rates.

Salinity levels in water are the next step in the water assessment process. While freshwater fish can tolerate certain levels of salinity, increases in water electric conductivity (EC) above a certain levels (e.g. 2 000 microSiemens) limits the growth of salt-intolerant vegetables. This would push agricultural producers to consider just salt-tolerant species, with potential risks of reduced profits owing to market conditions which may not be so receptive. In addition, the buildup of nutrients and salinity through the seasons as a result of imbalances between system intake (feed) and plant uptake could equally bring the aquaponic units to face increased salinity problems. These would need to be solved through moderate water dumping or modified management (limitation in feed use, cropping with salt-absorbing plants) that might reduce systems' profitability or productivity and may require a higher level of expertise in operators.

Climate is another major factor, as it will determine the extra cost for each unit to maintain the ideal environmental conditions for aquaponic food production. In general, regions where the average daily air temperatures throughout the year are 20-30 °C are the ideal for tropical fish, such as tilapia, and warmth-tolerant plants. Therefore, the choices of crops and fish significantly affect the costs if climatic control is needed to match the ideal growing conditions of both components. Moreover, regions where average daily air temperatures are favourable, but widely fluctuate during the day and night (i.e. highlands and mountainous regions), would be particularly problematic for fish production. This is because large changes cause stress to the animals.

Attention must also be paid to the seasons. Cold winter seasons will force aquaponic farmers to either invest in energy-demanding heating systems for their greenhouses or stop production entirely for certain months. It is thus important to study the production setup carefully and possibly find alternative species that avoid unproductive sections of the year.

Extended rainy seasons force farmers to protect their units with strong canopies or greenhouses, as large volumes of rain could damage crops, cause the systems to overflow or to dilute excessively the nutrients in water. However, if on the one hand this need requires extra investments, on the other it can be profitable in areas where traditional agriculture is severely limited owing to flooding or nutrient runoff. The same solution also pertains to wind, as the presence of a protected environment could bring higher yields and better quality of vegetable products, while traditional agriculture would struggle.

Summer seasons can cause water overheating. Although methods to keep temperatures relatively low during hot periods are quite simple and can be supported with proper system designs, it is possible that water temperatures would rise to suboptimal levels during extremely hot periods if no water cooling systems were used. This would limit farmers' vegetable growth and selection, even though it may not affect tropical fish or nitrifying bacteria.

LOGISTICAL AND MANAGERIAL FACTORS

Fish production is an important component of aquaponic operations. Easy access to aquatic animals is fundamental for farmers, as is the possibility to gain expertise on fish and knowledge of locally cultured fish.

Aquaponic expansion is thus limited in regions where there are no hatcheries, aquaculture production or extension services unless broodstock, fingerling and fish feed productions are all part of the aquaponic business plan. Even then, the investment appears riskier, as it implies longer periods to make the farm fully operative, and the need to dedicate more time for knowledge transfer and to scope potential local and regional markets where to sell the production.

At any location, access to electricity and appropriate water is essential. Particularly for electricity, the access to a constant and reliable power-grid is fundamental to secure the continuous functioning of pumps. The lack of this resource would severely limit the expansion of aquaponics unless low-yielding systems are designed to withstand power cuts of several hours without affecting fish survival. Aquaponic operations, especially if they are meant for commercial purposes, must rely on backup systems and generators, which increase the setup costs. Fish production is one of the most complicated aspects of aquaponics (particularly for farmers new to aquaculture), demanding daily management and care to avoid significant losses if any system failure occurs.

There must also be a market for key aquaponic components and monitoring tools (water test kits, pH meters, EC meters), which a local aquaculture market would normally facilitate. A determinant factor for the success of any aquaponic setup is the use of locally available materials and the sensible adaptation of systems to local contexts and resources. Failing this, it would be difficult to develop any cost-effective method of producing food.

Educational capacity is also a key factor when selecting specific locations within regions or countries. Aquaponics is a relatively sophisticated method of food production compared with traditional soil-based approaches. The method demands a higher level of understanding of this integrated ecosystem as well as the major factors that influence it (water, environment, nutrition, etc.). It also demands good individual aquaculture and horticulture knowledge that must be transferred and adapted to local contexts. The major challenge that aquaponics faces in order to become a sustainable option among illiterate or semi-illiterate farmers and/or end users is to reduce its levels of complexity by adapting the technology, or at least the concept, to local resources, needs and cultures. Adapting and contextualizing the systems would bring them closer to those fish/plant systems that have dominated agricultural practices for thousands of years. This would require a better knowledge among practitioners on how to design systems where every single component or material could reduce management needs to a minimum.

Where aquaponic food production is virtually non-existent within a specific region, it is beneficial to partner with local universities or agricultural extension institutes in order to develop knowledge on best practices and on how to develop aquaponics in a very simple and effective way.

SOCIAL CONDITIONS

Beyond the adoption of fish-plant systems as a competitive food production method, aquaponics has still not acquired a well-defined outlook. While aquaponics is widely accepted as an organic production method in North America, the same cannot be seen in Europe and this reduces its potential to gain premium prices.

Among consumers and researchers, there are also some concerns that aquaponic water is a vector of potential bacteria contaminations owing to fish faecal wastes.. Although different countries use different regulations on water safety, the development of aquaponics may be limited in those countries where the limit for bacteria is more stringent. This would require an increase in efforts to comply with local standards. (e.g. by using sterilizing technology), even though aquaculture wastewater is safer than other water sources.

On the other hand, aquaponics can provide an opportunity to produce safer food that is chemical-free and disease-free. In the case of the aquaculture industry, this may be an added-value characteristic that may raise interest in this production system. Recent concerns about pesticide use in agriculture have led many consumers in developing countries to buy safer products. These consumption patterns must be accurately monitored in the decision-making process as to whether aquaponics is feasible in a particular area or not.

SUMMARY OF ESSENTIAL REQUIREMENTS FOR AQUAPONICS AT DIFFERENT SCALES

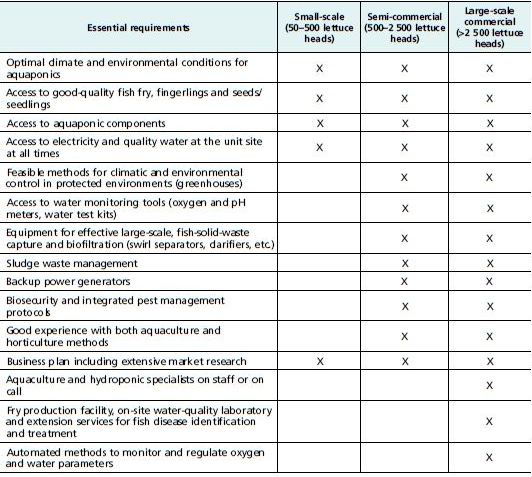

Table A6.1 summarizes the key considerations for aquaponic ventures on various scales.

TABLE A6.1

Key considerations for aquaponic ventures on various scales