3.3. Production

3.3.1 Background information

Duckweed growth is largely a function of available nutrients, temperature, light, and degree of crowding. The highest growth rate reported for Lemnaceae under optimal laboratory conditions is about 0.66 generations per day, which corresponds to a doubling time of 16 hours (DWRP, 1997).

Duckweeds generally double their mass in 16 hours to 2 days under optimal nutrient availability, sunlight, and water temperature. An individual plant, a small leaflet (frond), produces 10 to 20 daughter fronds during its lifetime, which lasts for a period of 10 days to several weeks. The daughter frond repeats the history of its mother frond. This results in an exponential growth, at least until the plants become crowded or run out of nutrients. Frequent periodic removal of the plants encourages continuation of the exponential growth.

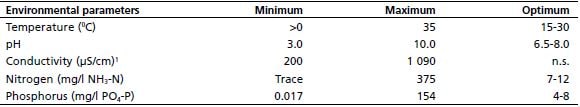

Table 3.4

Summary of some important environmental requirements of duckweed

1 Conductivity range found supporting growth of duckweed.

The individual clones of the same species may show quantitative variation in growth characteristics (Rejmankova, 1975; Porath, Hepher and Koton, 1979). In the Czech Republic, Rejmankova (1975, 1979) reported maximum dry matter yields of 3.14- 3.54 g and 7.09 g/m2/day from unmanaged fish ponds and outdoor tanks respectively, when weekly harvesting was done. Rejmankova (1981) further reported that an estimated annual net dry matter production of 7.5-8.0 tonnes/ha could be obtained, provided nutrients and crowding were not limiting and harvesting was frequent.

Culley and Myers (1980) and Said et al. (1979) working in the southern USA (9-10 months growing season) demonstrated that high nutrient lagoons and outdoor tanks (enriched with cattle manure) yielded the dry matter equivalent of about 15 g/m2/day (55 tonnes/ha/year) when regular daily harvesting was done to remove the excess. Said et al. (1979) reported an annual dry weight yield of 44 tonnes/ha or about 12 g/m2/day. Furthermore, Culley and Myers (1980) obtained an estimated average annual dry matter production of 23.3 tonnes/ha with daily harvesting ranging from 10 to 35 percent of the standing crop, depending on the season. In a sewage-fed culture system, the growth rate of Azolla spp., Spirodela spp. and Wolffia sp. were found to be 160, 350 and 280 g/m3/day, respectively (Reddy et al., 2005).

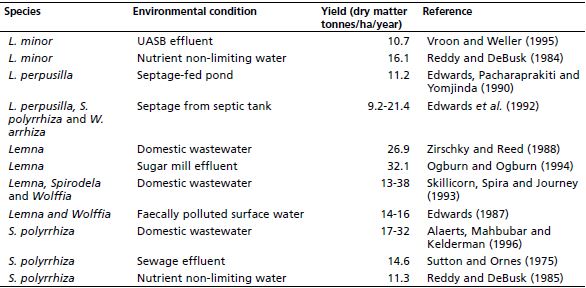

Table 3.5 presents the yields of various duckweed species under different environmental conditions. The values varied widely, ranging from 9 to 38 tonnes (DM)/ha/year. This wide range of productivity may be attributed to differences in species, climatic conditions, nutrient supply and environmental conditions. Many of the reported high yields are based on extrapolated data obtained from short-term growth from small-scale experimental systems rather than potential long-term yields from commercial-sized systems. Edwards (1990) reported extrapolated yields of ~20 tonnes (DM)/ha/year of Spirodela from experiments that were carried out for periods of 1-3 months in septage-fed 200 m2 ponds in Thailand; however, the yield declined to the equivalent of ~9 tonnes (DM)/ha/year over a 6 months period. Based on the available data and the foregoing discussion, it may therefore be concluded that an average annual yield of around 10-20 tonnes/DM/ha can be obtained from an aquatic environment where nutrients are generally not limiting and frequent harvesting is practised to avoid plant overcrowding.

3.3.2 Duckweed farming

Duckweed farming is a continuous process requiring intensive management for optimum production. Daily attention and frequent harvesting are needed throughout the year to ensure optimum productivity. Duckweed can grow in water of any depth.

Table 3.5

Yields of various duckweed species under different environmental conditions

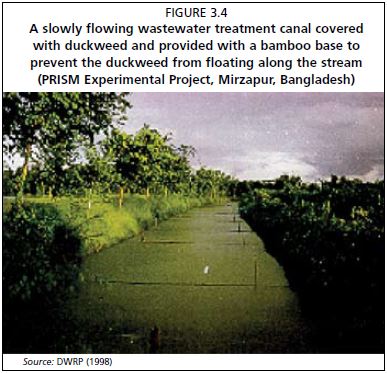

It will grow in as little as one centimetre of water. A pond depth of between 20 and 50 cm is generally recommended to reduce the potential sources of stress and to facilitate harvesting (Gaigher and Short, 1986). Duckweeds are prone to be blown into heaps by heavy winds or wave action. This allows light to penetrate the water column and would stimulate phytoplankton and algal growth. If the plants become piled up in deep layers, however, the lowest layer will be cut off from light and will eventually die (Skillicorn, Spira and Journey, 1993). Plants pushed from the water onto a bank will also dry out and die. Long narrow ponds that are sited perpendicular to the common wind are recommended. Dividing the pond into smaller segments by using bamboo can also mitigate the adverse effects of wind. An NGO called ‘PRISM’ applied a grid of bamboo poles (Figure 3.4) of approximately 5 x 5 m in large ponds and wide canals. This functioned satisfactorily for all conditions met up to that date in Bangladesh (DWRP, 1998). Lemma USA Inc. promotes floating barrier grids made of polyethylene that will reduce wind and wave action for its wastewater treatment plants. The sides of the ponds must preferably be vertical to prevent the plants from becoming stranded and at least 10 cm higher than the water level to accommodate heavy rains. The ponds must be fed with effluent through furrows rather than pipes because the latter tend to become clogged. Several inlets must be provided to spread the inflowing nutrients over the pond.

Since the growth of duckweed is dependent on water temperature, pH and nutrient concentration, these factors need to be balanced and maintained within reasonable limits for duckweed to thrive. The management strategies for duckweed culture should therefore focus on when to fertilize, harvest, and buffer; how much to fertilize and to harvest; and which nutrients to supply. Appropriate management should be aimed at maintaining a complete and dense cover of duckweed, low dissolved oxygen, and a pH of 6-8. A dense cover shuts out light and suppresses the growth of algae, which minimizes CO2 production from algal respiration and prevents its elevating effect on pH.

Any waste organic material that is readily biodegradable and has a sufficiently high nutrient content could be used for duckweed cultivation. The most economical sources of such waste materials are all kinds of animal manure, kitchen wastes, wastes from a wide range of food processing plants, biogas effluents, and slaughterhouse wastes. Solid materials, such as manure from livestock, night soil from villages, or food processing wastes, can also be mixed with water

Figure 3.4

A slowly flowing wastewater treatment canal covered with duckweed and provided with a bamboo base to prevent the duckweed from floating along the stream (PRISM Experimental Project, Mirzapur, Bangladesh)

4

Source: DWRP (1998)

and added to ponds at suitable levels. All wastewater containing manure or night soil must undergo an initial treatment by holding it for a few days in an anaerobic pond, before using it to cultivate duckweed.

Sutton and Ornes (1975) and Said et al. (1979) demonstrated the necessity of periodic additions of nutrients to small duckweed culture systems receiving municipal or dairy cattle wastes. Within 1-3 weeks, there was a noticeable drop in N, P and K within the plants. There was a corresponding drop in crude protein as the plant nitrogen declined. In unmanaged ponds, where duckweeds are not routinely harvested, the plants quickly become crowded and those beneath the surface die back.

Floating aquatic macrophytes – Duckweeds 37

Due to the high nitrogen requirement of duckweed and the relatively rapid loss of nitrogen from aquatic system, this nutrient tends to be limiting in ponds fed with wastewater (Gaigher and Short, 1986). Studies at Louisiana State University have shown that the nitrogen conversion efficiency from agricultural waste to duckweed is only about 30 percent under normal field conditions (Culley et al., 1981). Large-scale duckweed production therefore requires the availability of relatively large quantities of organic waste. The addition of cheap inorganic nitrogen could also therefore improve the wastewater conversion efficiency. The other nutrients that are needed for optimum growth of duckweed are phosphorus, potassium and trace minerals.

Fertilization

Urea is a suitable fertilizer, containing approximately 45 percent nitrogen, and is rapidly converted to ammonia under normal conditions. Muriate of potash (MP) and triple superphosphate (TSP) are commercial sources of potassium and phosphorus that are widely available in most countries and have been used where duckweeds have been farmed. Duckweed growth is not particularly sensitive to potassium or phosphorus once an adequate threshold has been reached. A ratio of TSP to urea of 1:5 worked satisfactorily in an experimental duckweed production programme in Bangladesh (Skillicorn, Spira and Journey 1993). Similarly, a ratio for MP to urea of 1:5 was found to be satisfactory for good production in the same duckweed production programme in Bangladesh.

Nutrients are absorbed through all surfaces of the duckweed leaf (Leng, Stambolie and Bell, 1995). There are at least three methods of fertilizer application including broadcasting, dissolving in the water column of the plot, and spraying a fertilizer solution on the duckweed mat.

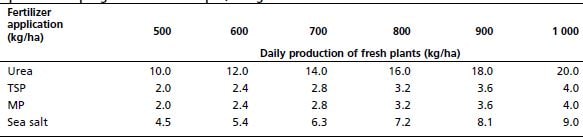

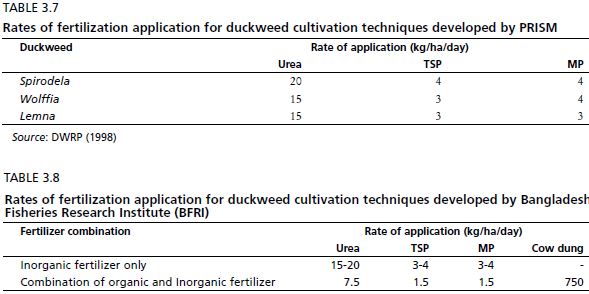

A fertilizer application matrix aiming to achieve variable daily production ranging from 500-1 000 kg of fresh duckweed per hectare was developed by PRISM in their experimental programme at Mirzapur, Bangladesh (Table 3.6). Furthermore, PRISM recommended daily fertilization rates for different types of duckweed (Table 3.7). The application rate varies from 21-28 kg/ha/day (amounting to >7 tonnes/ha/year) with an anticipated fresh biomass yield of 900-1 000 kg/ha/day. The daily fertilization rate for duckweed cultivation developed by the Bangladesh Fisheries Research Institute (BFRI) is presented in Table 3.8. The fertilizer schedules developed by PRISM and BFRI are very similar (Tables 3.7 and 3.8), except that BFRI recommended half the dosage of inorganic fertilizer when cow dung was used at the rate of 750 kg/ha/year.

Table 3.6

Dayly fertilizer application matrix for duck weed cultivation developed by PRISM in their experimental programme at Mirzapur, Bangladesh

Source: Skillicorn, Spira and Journey, (1993)

Seeding

Seeding is a highly important management measure since a full duckweed cover should be established before any algal bloom can start dominating the water body. The seed rate advised is 60 kg/100 m2 for Spirodela spp. and Wolffia spp. and 40 kg/100 m2 for Lemna spp. in order to obtain a dense cover in 3 days time (DWRP, 1998). From day four onwards daily harvesting can start.

38 Use of algae and aquatic macrophytes as feed in small-scale aquaculture – A review

Stress management

Stress management of the crop is necessary particularly during very hot and dry weather. ‘Dunking’ (dipping the duckweed below the water surface) once a day as a regular crop maintenance practice is recommended; this reduces the stress from overheating. Dunking consists of agitating the whole-cultivated area by hand until all plants have been physically immersed and wetted.

Plant density and harvesting rate

The productivity of duckweed increases with increasing plant density up to a density where the plants completely cover the surface of the water, and then remains constant. In order to maintain good productivity and prevent competition by phytoplankton/ suspended algae, the density must be maintained at this level or a slightly higher level. Competition between phytoplankton/suspended algae and duckweed is a potential constraint to the cultivation of the latter in nutrient-rich water. Phytoplankton smothers the roots of duckweed, which then turn yellow in colour, suffer a decline in growth rate, and eventually die. The development of an algal bloom can also reduce nutrient availability and thus eventually reduce the growth of duckweed.

An optimum standing crop density is a cover that is complete but which still provides enough space to accommodate rapid growth of the colony. In the PRISM experimental programme at Mirzapur, Bangladesh a base Spirodela density of 600 g/m2 was shown to yield a daily incremental growth of 50 to 150 g/m2/day (Skillicorn, Spira and Journey, 1993). This is equivalent to a daily fresh (wet weight) crop production rate of 0.5 to 1.5 tonnes/ha. These authors recommended a plant density of 400 to 800 g/m2 for optimum production. BFRI (1997) obtained duckweed production of 700- 1 500 kg/ha/day at plant densities varying from 400-600 g/m2 in their experimental programme at Mymensingh.

High-density populations contain a high ratio of old fronds, which can be detrimental in various ways. Duckweed should therefore be harvested frequently, preferably daily. The standing crop density, or the weight of fresh plant per square meter, will determine the amount and timing of harvests. Daily harvesting of the incremental growth of the duckweed plot - averaging approximately 100 g/m2/day is recommended (Skillicorn, Spira and Journey, 1993). Culley and Myers (1980) obtained an annual dry weight production of 23.31 tonnes/ha with daily harvesting ranging from 10 to 35 percent of the standing crop each day, depending on the season. Edwards (1990) recommended 25 percent harvesting of the duckweed biomass when duckweed growth completely covers the pond, with the remaining 75 percent left in the pond for further growth.

Table 3.7

Rates of fertilization application for duckweed cultivation techniques developed by PRISM Duckweed Rate of application (kg/ha/day)

Table 3.8

Rates of fertilization application for duckweed cultivation techniques developed by Bangladesh Fisheries Research Institute (BFRI)

Source: DWRP (1998)

Source: BFRI (1997)

This author opined that this harvest could be made every 1-3 days, depending on the season.

Duckweed in wastewater treatment

Ferdoushi et al. (2008) tested the efficacy of Lemna and Azolla as biofilters of nitrogen and phosphate in fish ponds in Bangladesh and found that they removed the excess amount of nutrients from the water body and maintained sustainable environmental conditions. Duckweeds have received much attention because of their potential to remove contaminants from wastewater (Leng, Stambolie and Bell, 1995). Duckweed wastewater treatment systems have been studied for dairy waste lagoons (Culley et al., 1981), raw domestic sewage (Oron, 1994; Skillicorn, Spira and Journey, 1993; Alaerts, Mahbubar and Kelderman, 1996), secondary effluent (Harvey and Fox, 1973), waste stabilization ponds (Wolverton, 1979) and fish culture systems (Porath and Pollock, 1982; Rakocy and Allison, 1981). The basic concept of a duckweed wastewater treatment system is to farm local duckweed on the wastewater requiring treatment. Duckweed has a high mineral absorption capacity and can tolerate high organic loading as well as high concentrations of micronutrients.

Duckweed wastewater treatment systems remove, by bioaccumulation, as much as 99 percent of the nutrients and dissolved solids contained in wastewater (Skillicorn, Spira and Journey, 1993). These substances are then removed permanently from the effluent stream following the harvesting of a proportion of the crop. The plants also reduce suspended solids and BOD by reduction of sunlight in lagoons. Duckweed systems distinguish themselves from other effluent wastewater treatment mechanisms in that they also produce a valuable, protein-rich biomass as a by-product.

Depending on the wastewater, the harvested crop may serve as an animal feed, a feed supplement supplying protein/energy and minerals, or a fertilizer. The question of toxic elements must be considered if certain types of waste material serve as the nutrient source for duckweed culture; for example, duckweed will absorb heavy metals and insecticides from the wastewater. It may, therefore, have to be decontaminated prior to feeding to animals if heavy metals are present in the water.

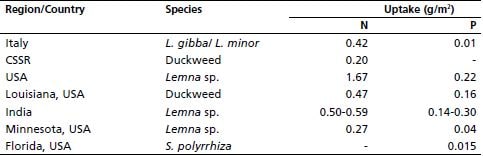

Landolt and Kandeler (1987) reported that of all aquatic plants, Lemnaceae have the greatest capacity in assimilating the macro-elements N, P, K, Ca, Na and Mg. Table 3.9 presents some data on daily nitrogen and phosphorus uptake efficiency by duckweed. The results from the various studies are not comparable because different species are used and different climatological and operational conditions were applied. Temperature may have a significant effect on nutrient uptake efficiency as has also been observed for other aquatic plants.

Table 3.9

Daily nitrogen and phosphorus uptake by duckweed

Source: adapted from DWRP (1997)

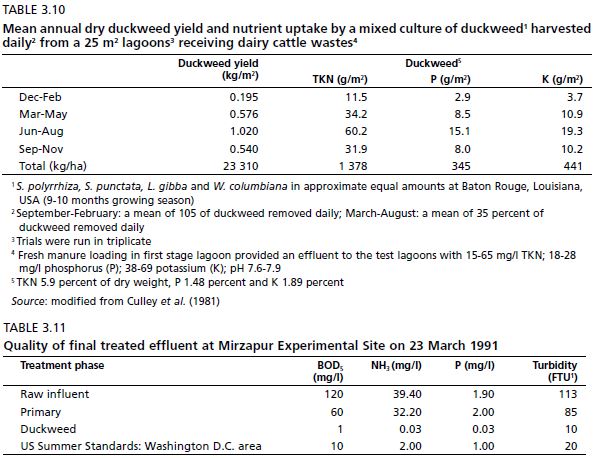

Culley et al. (1981) made a comprehensive study on nutrient uptake from wastewater by a mixed culture of duckweed (Table 3.10). This shows that duckweeds are capable of removing considerable amounts of organic wastes from natural water. An annual

40 Use of algae and aquatic macrophytes as feed in small-scale aquaculture – A review

nutrient removal capacity covered by Lemnaceae of 1 378 kg TKN, 345 kg P, and 441 kg K per hectare of water area was calculated.

Summarizing the results of PRISM Experimental Site at Mirzapur, Skillicorn, Spira and Journey (1993) reported that treating an average flow of 125 m3/day of hospital, school, and residential wastewater produced by a population of between 2 000 and 3 000 persons, the 0.6 ha duckweed treatment plant produces a final treated effluent that exceeds the highest quality standards mandated in the USA (Table 3.11). These authors also estimated that a typical duckweed wastewater treatment plant would yield a daily harvest of up to one ton of duckweed plants (wet weight) per hectare or 90 kg per hectare of dried, high protein duckweed meal each day.

Table 3.10

Mean annual dry duckweed yield and nutrient uptake by a mixed culture of duckweed1 harvested daily2 from a 25 m2 lagoons3 receiving dairy cattle wastes4

Source: modified from Culley et al. (1981)

Table 3.11

Quality of final treated effluent at Mirzapur Experimental Site on 23 March 1991

Source: Skillicorn, Spira and Journey (1993)