5.1.4 Growing larvae more efficiently

Mention has been made earlier in this section of methods that can be employed to improve the efficiency of larval culture, either by operating the culture tanks on a flow through of seawater or by rearing larvae at higher densities in static water tanks. In fact, the two methodologies can be combined to good effect in increasing production where space is limited with the added benefit of reducing the labour component in husbandry.

Although some hatcheries are beginning to turn to flow-through, the practice is not yet widespread. There is, however, ample scope to improve productivity by raising the density at which larvae are reared either by using existing equipment more efficiently or by investing in electronic devices to control feeding. The usual larval densities can be doubled or trebled by feeding to the number of larvae in a tank and their size, rather than by adding food to the water volume to a certain food cell density per unit volume, irrespective of the number and size of larvae. But if larval densities are further increased then the rate at which the feed is supplied becomes critical and needs to be continuously monitored. This approach is more suitable for the hardier species. If mortalities do occur for one reason or another, the effects in terms of lost productivity can be drastic. Most hatcheries prefer to opt for the more cautious approach.

5.1.4.1 High density culture

The rate at which food cells are ingested by larvae of different sizes (or weights) of the bivalve species being cultured needs to be known. This information is shown later in Table 12 (part 5.2.3.2) For three commonly cultured species when grown at 24+1oC. Where such information is lacking it will need to be determined experimentally or by the “trial and error” principle.

Knowing the relationship between larval size and food cell ingestion rate, it is a simple matter to calculate how much food needs to be added to the tank during the next 24-h period for a given number of larvae in culture of a particular mean shell length. Details of the calculation with worked examples and an explanation are given in the next section (part 5.2.3.2). At higher densities than the norm it will be necessary to provide part of the ration as a bulk feed at the beginning of the day; the remainder being dosed at a constant rate by drip feed or peristaltic pump over the next 24 hours.

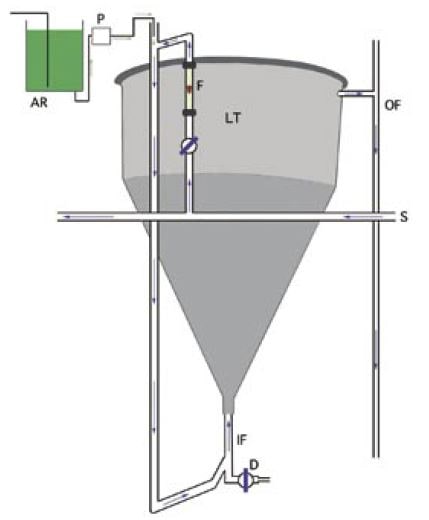

At more than 20 000 larvae per l, particularly as they approach metamorphosis, feeding rate becomes more critical. It is more detrimental to over-feed larvae than it is to under feed them. The amount of faecal waste and metabolites will accumulate in the culture water and can give rise to great increases in bacterial numbers. This can reduce feeding rate and result in more food being added to the tank than can be filtered by the larvae when added at a constant fixed rate. The solution has been tackled experimentally by the use of electronic sensors and control equipment to continuously monitor the food cell density in the culture tank (Figure 62). [A full explanation is given in Higgins et al. (1987) – see suggested reading list].

Figure 62: Experimental automatic control of food cell density in high-density cultures of bivalve larvae. AR – chilled, aerated algal reservoir containing the daily food ration; P – peristaltic pump which delivers the required amount of algae upon demand; C – control equipment containing a relay that switches the pump on when the sensor (S) detects a decrease in food cell concentration in the larvae tank (LT) below a certain pre-set threshold. This device utilizes an infra-red transmitter and receiver and could be greatly improved with modern electronics.

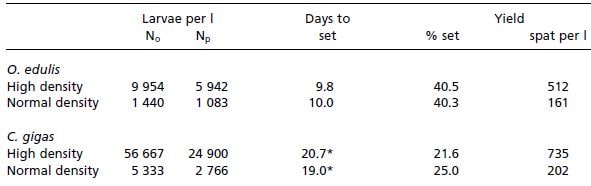

A summary of comparative results is given in Table 12, which includes data from trials with European flat oyster and Pacific oyster larvae.

Table 12. The average number of larvae stocked initially (No) and surviving immediately prior to settlement (Np) in 5 comparisons of high and normal density rearing with the European flat oyster, O. edulis, and 3 comparisons with the Pacific oyster, C. gigas. The number of days to the onset of settlement and information on average spat yields (both as % of the initial number of larvae and as spat per l of water used during culture) are also shown.

* Days to set from the D-larva stage allowing a 4-day settlement period from the time settlement began.

5.1.4.2 Flow-through culture

The impetus to develop flow-through methods of larval culture stem from a number of objectives. Larvae of some species are less tolerant than others to generally used methods of culture in hatcheries. Those of the various pectinid species are a good case in point. They usually exhibit higher mortality rates and are not as amenable to high

density culture in static systems.

Other hatcheries are testing the potential of flow-through technology to make better and more efficient use of available resources. There may be the need for greater production within physical space constraints or to reduce labour costs and time spent in larval husbandry. Flow-through culture does offer these benefits. Time can be saved in raising the density of larvae without the need to drain statically operated tanks 3 or 4 times each week. The method may be wasteful in the use of cultured algae in that water is continuously being exchanged, albeit at a slow rate, and is run to waste. But the food is relatively inexpensive to produce at the required volumes at this stage in the production cycle.

Tank design is important when considering flow-through. Larvae need to be retained within the tank and the volume large enough to ensure that added food has a sufficient residence time to be eaten. The exchange rate needs to be sufficient to prevent metabolic wastes and debris from accumulating, yet there may still be the need to flush out the tank periodically after cleaning the interior surfaces. The general approach is commonly used in culturing the early pre-feeding stages of marine fin-fish, e.g. Halibut, where purpose made tanks are available and can be adapted with minimal alteration. Rather than the flat-bottomed or steeply tapering conical tanks generally used in bivalve larval culture, these conical tanks have shallowly tapering, long cones (Figure 63).

Figure 63: A typical arrangement for flow-through larval culture. See text for a description. Arrows show the direction of flow of both algae and seawater.

The rate of flow of suitably treated seawater (from the delivery pipe, S) is controlled and adjusted by a diaphragm valve and flowmeter (F). Depending on the density of larvae, the flow is adjusted such that the total daily throughput (IF – in-flow, OF – out flow) is the same or greater than the total tank (LT – flow-through larval tank) volume that the number of larvae would require when cultured at normal densities. If, for example, larvae are normally cultured at 5 000 per l in a 500 l tank, then 20 000 larvae per l in a flow-through tank of the same volume will require a minimum throughput of 2 000 l per day. Larvae are retained in the tank by a large diameter “banjo” filter fitted with a suitable aperture mesh screen (see Figure 64 for details).

The tank is fitted with a drain valve (D), which also serves as the input port for a “salt plug” of saturated brine solution. When the in-flow is switched off, this “salt plug” of 2 or 3 l volume is gravity-fed into the drain and the valve closed. Living larvae will swim to the water surface and thereby avoid the dense salt solution, which traps the dead and moribund. After a few minutes, the drain is opened a fraction to eliminate the “salt plug” and the dead larvae, much in the same way as dead marine fish eggs are accumulated and eliminated from incubators.

Larvae are supplied with the required food ration by peristaltic pump (P) from a cooled and aerated algal reservoir (AR). The quantity and rate at which the ration is supplied depends on the number of larvae, the size they are and the flow rate through the tank (refer to parts 5.1.4.1 and 5.2.3.2). Mean shell length can be determined by taking daily samples, but survival is more problematic. An estimate of mortality can be obtained by sub-sampling the volume of saturated brine collected after a “salt plug” and counting the dead larvae it contains. This can be done at 2 to 3 days intervals to keep track of survival.

Internal surfaces of flow-through tanks need to be cleaned with a soft-bristle brush, attached to a pole of suitable length, at least once during the culture period of a batch of larvae. The flow rate should be increased during cleaning to flush out the dislodged debris.

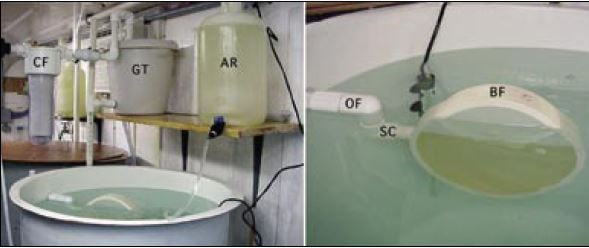

Figure 64: Detail of the top of an experimental flow-through tank showing the “banjo” filter (BF) attached to the out-flow pipe (OF). In this example, seawater filtered to 1 ?m by a filter cartridge (CF) is supplied to a gravity tank (GT) from which it flows at a controlled, constant rate into the base of the larvae tank. Food is drip-fed into the tank from an algal reservoir (AR). The “banjo” filter is made from a 20 cm diameter section of PVC pipe and is fitted both sides with 60 ?m nylon mesh screen, solvent cemented to the cut faces of the cylinder. A short length of suitable diameter PVC pipe is welded into a hole drilled through the plastic to connect with the out-flow pipe. Large diameter “banjos” are recommended to reduce the per unit area force generated by the out-flow. They should be totally, or almost totally, submerged and need to be cleaned daily. For this purpose, the “banjo” is a push-fit into a swivel coupling (SC) made from a pair of 90o PVC elbows. This coupling can be swivelled upwards to raise the filter above the water level for removal and cleaning, or replacement.

Rearing larvae in flow-through tanks does have disadvantages but they are potentially more than outweighed by the benefits. Since larvae are not graded on a regular basis as in static culture, considerable variability in size will develop over time. Also, larvae will need to be transferred to settling tanks when they reach the pediveliger stage. This is standard practice in many hatcheries but not in others, where larvae are allowed to set on the sides and bases of the larval rearing tanks from which they are later removed.

Removing attached pediveligers and spat from the internal surfaces of shallowly tapering cones will be extremely difficult. Settlement tanks will be needed, particularly for late-stage larvae of the various oyster species that cement themselves to surfaces (see 5.4.3).