1. Introduction

Cage aquaculture has grown rapidly in recent decades and is currently undergoing swift changes in response to pressures from globalization and an escalating worldwide global demand for aquatic products. There has been a move towards clustering existing cages as well as towards the development and use of more intensive cage-farming systems.

In particular, the need for suitable sites has resulted in cage aquaculture accessing and expanding into new untapped open-water culture areas such as lakes, reservoirs, rivers and coastal brackish and marine offshore waters.

In 2007, the Food and Agriculture Organization of the United Nations (FAO) published a report entitled Cage aquaculture: regional reviews and global overview (Halwart, Soto and Arthur, 2007). This report provides an assessment of the situation and future prospects of cage aquaculture around the globe, recognizing the importance of cage aquaculture and its key role for the future growth of the aquaculture sector.

The regional reviews offer information on the history and origin of cage aquaculture, outlining major issues and challenges as well as highlighting specific technical, environmental, socio-economic and marketing issues that cage aquaculture faces and/ or needs to address in the future.

The ever-increasing competition for land and water space, along with the growing market demand for marine fish and other sea products, as mentioned above, are some of the elements that are motivating the aquaculture engineering industry and entrepreneurs in the development of farming structures in open waters. In the past couple of decades, a variety of fish containment structures, typically referred to as fish cages, have been designed, tested and commercially produced. These structures vary in design, size and materials used as they are intended for diverse environments, ranging from relatively protected to highly exposed and dynamic sites, either as floating or submerged underwater structures and adopting a number of technological solutions to facilitate fish stock husbandry and management.

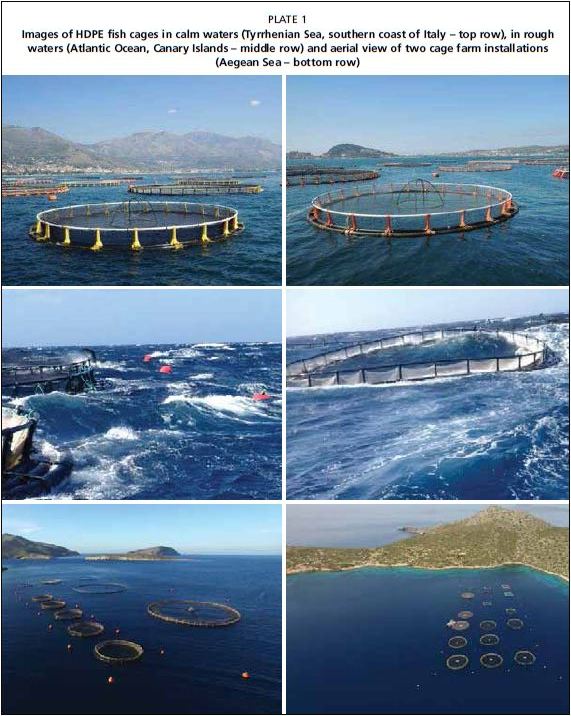

This technical manual focuses on the technical, structural and operational issues of high-density polyethylene (HDPE) floating cages, as they are currently widely used in modern industrial marine aquaculture in many parts of the world owing to the versatility of the materials used, the simplicity in the various farming operations and the relatively contained investment capital required (Plate 1). The main structural elements of these cages are the HDPE pipes, which can be assembled in various ways in order to produce collars of different sizes and shapes. The HDPE pipes, held together by a series of brackets with stanchions disposed throughout the entire circumference, form the floating collar ring, which is the main structure on which the fish net pen is secured. These gravity cages maintain the net pen shape and volume through a system of weights, also known as a sinker system, fixed at the bottom end of the net.

This manual provides the reader with highly practical and technical information on the design and components of a typical HDPE cage, on how to assemble a cage collar and on how to install a net pen. It also provides comprehensive information on the grid mooring system and installation. Finally, it presents information on farming operations, including maintenance and control of the farming structures, stocking of the farmed fish, feeding, harvesting and packaging, with a focus on practical aspects and routine management operations. The first chapter of this handbook highlights the importance of proper site selection in marine cage farming, briefly summarizing environmental factors such as wave exposure, water depth, oxygen levels, and water temperature, all of which influence farming operations and may determine the success of a fish cage farm if they have all been taken into due consideration during the planning stages of a business venture.

PLATE 1

Images of HDPE fish cages in calm waters (Tyrrhenian Sea, southern coast of Italy – top row), in rough waters (Atlantic Ocean, Canary Islands – middle row) and aerial view of two cage farm installations (Aegean Sea – bottom row)