Collar installation

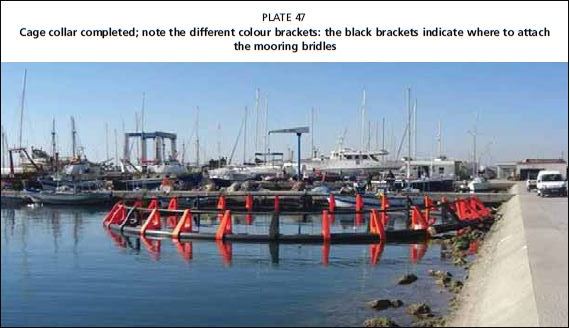

Once the cage collar is completed, it can be launched by being slid into the water (Plate 47).

This operation needs to be performed carefully because pipes may kink or buckle if bent beyond their critical limit. Cage components can also be damaged when sliding across the dock.

To minimize the risk of damage, cage collars can be reinforced with some diametrically positioned bracing lines that will maintain the collar’s circular shape and avoid excessive bending of the pipes.

PLATE 47

Cage collar completed; note the different colour brackets: the black brackets indicate where to attach the mooring bridles

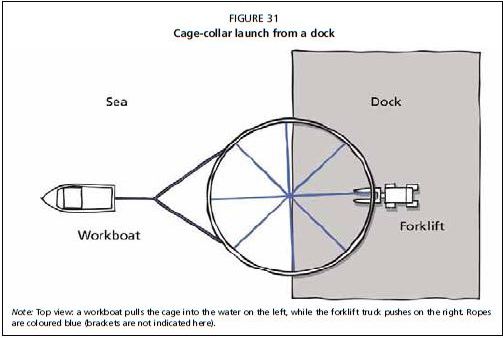

The cage collar can be launched using either a forklift truck or a workboat, or by a combination of the two. Figure 31 provides a schematic view of a cage collar launch- the towing rope and diametrically positioned ropes are represented by blue lines.

Note: Launch sites always differ, the important thing to remember is to not damage the cage in any serious way. For example, if having to drag it over a rocky area (rip-rap) before entering the water, it is advisable to have material (pipes, beams) under the cage that it can slide easily.

The cage can be easily towed with a suitably sized boat with outboard engine. It is important that two "V-shaped" towing ropes, or bridles, are installed to distribute the pulling force on at least two points on the cage (Figure 31).

FIGURE 31

Cage-collar launch from a dock

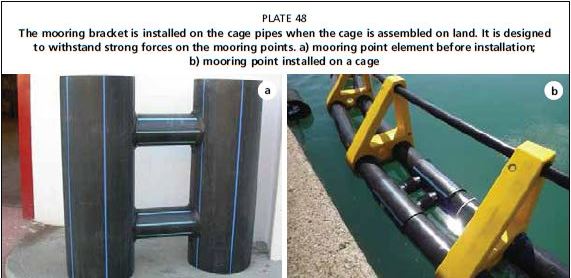

The rope attachment points on the cage must connect to the inner pipe. The distance between the two ropes should be at least 4 m for a cage up to 70-80 m in circumference. Some cage models may have a mooring bracket specially designed to withstand high tensioning forces. If a mooring bracket is present, the rope can be attached here (Plate 48). These are generally installed if to wing over long distances (such as in tuna tow cages).

PLATE 48

The mooring bracket is installed on the cage pipes when the cage is assembled on land. It is designed to withstand strong forces on the mooring points. a) mooring point element before installation; b) mooring point installed on a cage

The mooring bracket can double the thickness of the tube, and it also prevents the bridle or tow rope from sliding around the HDPE pipe, thereby avoiding abrasion of the ropes on the plastic components of the cage.

It is better to install the internal diametric bracing lines before starting the cage tow.

If the tow is undertaken with the net installed, a minimum distance of 50 m must be maintained between the boat and the cage to prevent the propeller thrusting against the net. This distance should be increased to a minimum of 100 m if there are fish inside the net cage.

A fast towing speed will create a downward force on the leading edge of the collar pipes, on the side opposite to the boat (i.e. the inner edge of the trailing section of the collar). It is therefore advisable to attach floats (fenders, buoys, or other floating material) on these sections of pipe.

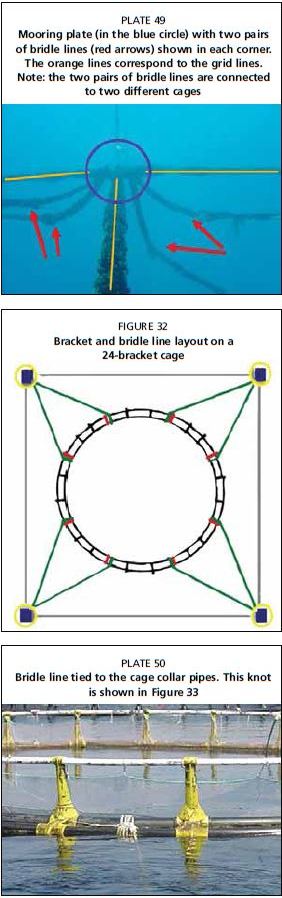

On the farm site, each cage collar is moored onto the grid system through bridle lines connected to the grid plates (Plate 49). Usually, two lines from each plate are available for each collar mooring, and as the cage is to be moored onto four plates, a total of eight lines are used for each cage. It may be necessary to have 3 lines for each plate (a total of 12 lines per cage), for larger cages (> 25 m diameter), or in more exposed sites.

The layout of bridle line attachments to a collar is depicted in Figure 32. Four pairs of bridle lines (green) connect each corner plate (blue) with the collar. Attachment points on the cage must be symmetrical. The bridle line attachment points can be easily identified by using different-coloured brackets (see Plate 47). The regular positioning of the bridles on the collar is very important to ensure equal weight distribution. Note that each bridle line is tied onto the farther side of the brack et and, for each pair of bridle lines one is on the left side of the bracket while the other one is on the right side.

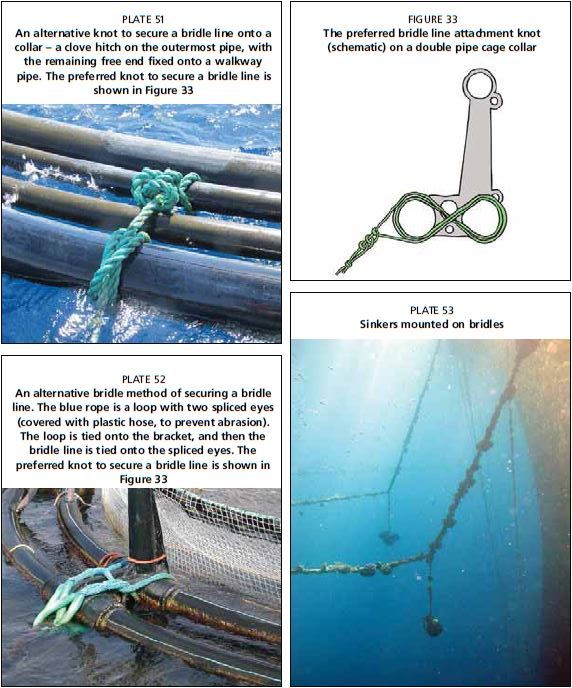

The bridles are critical components that may affect the integrity of the cages if not properly installed. It is important that the bridle system is pre-designed, pre-measured and marked to avoid any mistake in the installation phase. Several different methods can be used for tying the bridle line onto the cage collar (see Plates 50-52 and Figure 33). The most commonly used knot is shown in Plate 50 and Figure 33. The bridle line is passed over the

external pipe first and then spooled around the pipes alternately several times before being hitched onto the bridle line running from the grid plate.

If bridle lines are buoyant (e.g. polypropylene), they can hinder boat movements, and may become entangled in the boat’s propellers or around the rudder. To prevent this, a small sinker (small concrete block or a small section of chain) can be added to each bridle line (Plate 53).

Net installation

The following procedures describe the general process for net installation (net characteristics are described in Chapter 5). Installation procedures for a new net may differ from farm to farm; they are also constantly being refined “in the field” year after year by each team of workers.

The net is unpacked on land and carefully checked to verify that there are no manufacturing defects.

If the attachment points of the net are spliced eyes, an adequate number. of connecting lines (the green lines in Figure 34) should be prepared and assembled alongside the net. The number of lines for connecting the net to the brackets will be double the number of the net's vertical lines, and each will be about 1.5-2 m long (the actual length will depend on the brackets' design). The number of lines for connecting the net to the sinker system will be equal to the number of vertical lines, and these will be several metres long. The length of these ropes is variable depending on the length of the net and the model of sinker system. The net is lifted inside the cage collar with a boat crane. Its top rope is fixed onto the brackets at the handrail level, and the waterline rope is fixed onto the base of each bracket.

? Divers connect the base rope to the sinker system through the connecting lines.

Note: The "jump net" (the portion of net between the top rope and the waterline rope) must be left loose. All of the net's weight must be distributed along each of the waterline ropes' connections.

75