5. Fibres, netting and ropes

FIBRES

The recent expansion in fish cage culture has been largely driven by the industrial development of new materials and polymers. Ongoing research on new polymeric fibres is continuously providing innovative materials for new nets and ropes.

Synthetic fibres play a key role in the fish cage aquaculture industry subsector, as they are used to manufacture both netting and ropes. The same polymers can be used for both net cages and moorings, resulting in similar issues in terms of robustness, maintenance and reliability.

The most common synthetic polymers for nets and ropes are nylon or polyamide (PA); polyester (PES); polypropylene (PP); and high-performance polyethylene (DyneemaTM or SpectraTMM). Polyester and polypropylene fibres can be braided together to create netting with the combined characteristics of the two polymers. All these polymers are non-water-soluble; they have good chemical resistance and are therefore well suited for use in the marine environment, providing excellent and long-lasting durability and reliability.

Density

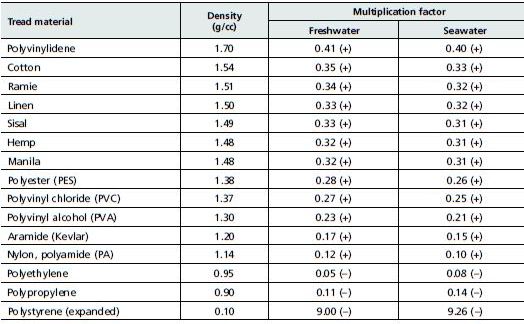

Table 18 shows the different densities, indicating their floating or sinking behaviour, of the main fibres used in fish farming.

TABLE 18

Textile fibres, density and multiplication factor for estimating weight in the water

The weight of an object varies depending on the substance it is immersed in. Based on Archimedes' principle, an object can either sink or float depending on the relative density of the object itself and the surrounding substance. The multiplication factors in Table 18 are used to find the actual weight of textiles in water..

For example:

25 kg of nylon netting in air has the following multiplication factors: freshwater: 0.12 (+); seawater: 0.10 (+), so the final weight:

- in freshwater is: 25 kg x 0.12 (+) = 3.0 kg;

in seawater is: 25 kg x 0.10 (+) = 2.5 kg.

Textiles with a density < 1 will float; therefore, multiplying the weight by the multiplication factor will indicate the buoyancy.

As a further example: polystyrene has a multiplication factor of 9.26 (-) in saltwater; therefore 1 kg of polystyrene submerged in water will have a relative weight of -9.26 kg, or a buoyancy of 9.26 kg.

Polyamide (PA), or nylon

• Sinks (density = 1.14)

? Very resistant to breaking ? Very resistant to abrasion High elongation (stretch)

• Excellent flexibility

High capacity for absorbing different resins

Nylon is the most commonly used fibre in cage aquaculture. Netting for cages, mooring lines and lines used for attaching the net to the collar are mostly made with nylon.

Nylon has poor resistance to UV light and will deteriorate, thus all the equipment made with this fibre must be properly stored away from direct sunlight. The longer nylon nets or ropes are exposed to UV light, the greater the decrease in breaking load and overall strength, resulting in a higher risk of structural breakages.

Nylon is highly elastic (23 percent at breaking load), which can increase the length of each component after a working period of few months by about 10 percent. Therefore, a nylon mooring system will need to be tensioned again a few months after it has been deployed. Nylon net cages will increase in depth by 5-10 percent owing to the elongation of ropes and netting subjected to loads from biofouling or the sinkers on the net.

Nylon fibres can also shrink, causing problems in netting. After several net-washing operations, it is possible that the horizontal dimensions of the cage can be reduced by 3-5 percent. In the net assembly, consideration must always be made for this factor and extra netting built into the design to allow for this phenomenon.

Polyethylene (PE)

• Floats (density = 0.94-0.96)

• Good resistant to abrasion ? Good elasticity.

Polyethylene and high density polyethylene nets are often used as anti-bird/anti- predator nets due to their light weight and resistance to abrasion. Braided or twisted knotted nets are being used in salmon growout in locations where nets treated with antifouling are banned and frequent on site net cleaning is required.

Polyester (PES)

Sinks (density = 1.38)

• Highly resistant to breaking

• Good flexibility

Low elongation

Highly resistant to UV exposure

Polyester has very good resistance to UV light, so it is commonly used for nets that have to be exposed to the sunlight, such as bird nets mounted above the cages, and anti-abrasion net panels around the waterline of the cage.

Compared with nylon, PES is about 20-25 percent heavier (to achieve the same breaking load), but PES has the advantage of not absorbing water, whereas nylon can absorb up to 10 percent of water.

The heavier characteristics of PES can be of value in nets exposed to strong currents because the low elongation of the material ensures that the net will maintain its shape. relatively well.

Polypropylene (PP)

Floats (density = 0.92)

Resistant to breaking

Highly resistant to abrasion

Polypropylene netting is not commonly used in cage net manufacturing, but is instead often used for predator nets (commonly for bird protection nets). Polypropylene nets with a large mesh size and large twine thickness are also used as spat collectors in mussel culture, because the buoyancy of the fibre contrasts the weight of the mussels that attach to the net.

High-performance polyethylene (HPPE) Floats (density = 0.91)

• Excellent resistance to breaking Resistant to abrasion

High-performance polyethylene fibre, such as Dyneema TM or SpectraTM produced by DSM (a division of Royal DSM NV in the Netherlands) or by Honeywell (United States of America), was invented in the 1990s. This fibre has increasingly been used in aquaculture, mainly for net production. The main characteristics of this fibre are the reduced elongation (3.5 percent at breaking load) and the exceptional breaking load compared with other fibres of the same thickness.

Net pens manufactured using netting with HPPE have several advantages:

The strength of HPPE results in a smaller twine diameter and, therefore, lighter, stronger and more-efficient nets.

• HPPE netting is more resistant than other fibres to fish bites, breaches and other damage (especially with biting species such as the gilthead seabream, Sparus aurata). HPPE net has twice the longevity of nylon nets.

However, HPPE nets cost two to three times more than traditional nylon nets, while HPPE ropes can cost up to ten times as much as conventional ropes.

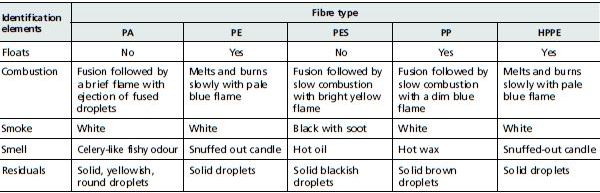

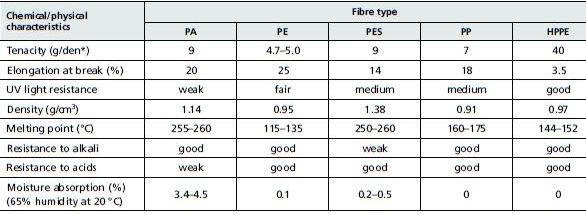

Fibres may seem very similar at first sight, but some empirical criteria for a quick field-check can be considered for correct identification (Table 19). Table 20 provides chemical and physical characteristics of those synthetic fibres most commonly used in aquaculture that can help for an empirical identification.

TABLE 19

Empirical criteria for identification of synthetic fibres

TABLE 20

Chemical and physical characteristics of synthetic fibres

* den = Denier.