Chapter 3 Hatchery: facilities and techniques for larval culture

3.1 HATCHERY FACILITIES

The goal of the hatchery is to produce quantities of juvenile scallops by inducing spawning of adults, and rearing larvae and post-larvae under controlled conditions. For reliable production of larvae and post-larvae, strict adherence to protocols for each stage of culture and routine chores for daily care is necessary. Throughout larval and post-larval rearing, cleanliness in the hatchery is essential to prevent large-scale mortality and loss. For this reason, details of routine cleaning of seawater supplies and tanks followed in Bermuda are provided in this Chapter. These protocols have proved extremely valuable at the Bermuda hatchery, in ensuring regular maintenance.

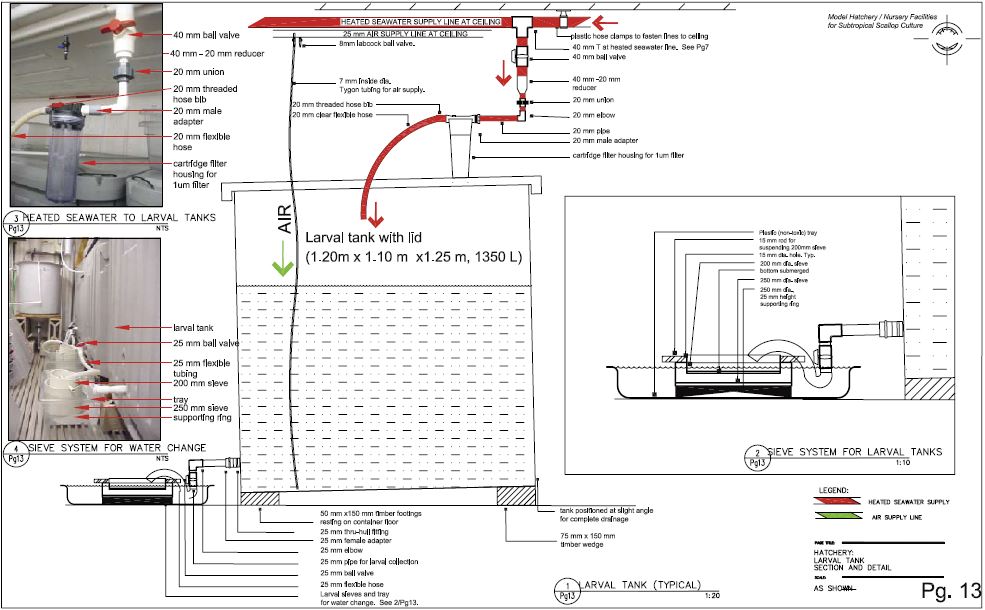

Technical drawing, Pg. 13

Hatchery: Larval tank section and detail

This Chapter describes the hatchery facilities necessary for the development of eggs to straight-hinge stage (Figure 1.7), and for the rearing of larvae to the time of settlement.

The overall plan of the facility, showing larval tanks and air compressor is seen on technical drawing – page 6A and described in Chapter 1. A total of four square insulated “BONAR” tanks (1 344 litres total capacity) are used for larval rearing. Larval tanks are supplied with compressed air and heated seawater filtered twice to 1 µm. Description of the heating system and heating lines in the hatchery are provided in Chapter 1 (see Section 1.1.3) and drawings are on technical drawings – pages 5A and 5B.

3.1.1 Larval tanks

Refer to Technical Drawing – page 13. In general, the larger the tank the better; it is preferable to minimize the surface area to water volume ratio as surfaces tend to have higher numbers of bacteria. In Bermuda, square tanks with maximum volume of 1 344 litres are used as standard larval rearing vessels. These insulated tanks have double walls filled with foam, and molded legs; they are often used for fish transport, for their insulating capacity, and for this reason, they were selected for scallop larval rearing in Bermuda, as larvae are cultured at a temperature higher than the ambient. Lids are provided with the tanks, and are used for maintaining a constant seawater temperature. For larval rearing, tanks are filled to a maximum of 1 000 litres, and hence referred to throughout this manual as 1 000 litres tanks. Larval tanks are filled with heated seawater, supplied from the heating unit (see Chapter 1). As seen in the technical drawing diagram – 1/Pg13, the seawater line is affixed to the ceiling by plastic hose clamps. A 50 mm T is glued in-line for supply of seawater to two larval tanks. A 50 mm ball valve regulates the flow of seawater to the tank; it is reduced to 20 mm by a 50 mm to 20 mm bushing. A 20 mm union connects the heated seawater supply to a 20 mm elbow fitted to a cartridge containing a 1 µm filter. The 20 mm union above the cartridge allows for dismantling of the cartridge-housing unit for cleaning in-between water changes. This filter system provides additional filtration after heating and prior to delivery to the larval tank. The cartridges used have 20 mm fittings included; on the outflow a 20 mm ID clear flexible hose is used to fill the larval tank. The technical drawing photo – 3/Pg13 illustrates the filter set up in detail.

The air supply to the larval tank is also illustrated in technical drawing – 1/Pg13. Air supply is regulated by labcock ball valves and connected to the airline (see diagram – 2/Pg 7). A 7 mm ID Tygon tube is fitted to a labcock ball valve running down the length of the tank. For larvae, a low volume air flow is provided, equivalent to one bubble at a time, sufficient to oxygenate the tank and prevent algal cells from sinking.

In the hatchery, larval tanks are placed directly on the floor, resting on timber footings at each corner. A gentle slope is provided for complete drainage of the tank, by raising the back side using additional timber wedges. The drain valve is located on the front of the tank. For controlled drainage, necessary for collecting of larvae, a 25 mm thru

hull bulkhead fitting is glued into an existing drain hole. A 25 mm female adapter is threaded into the thru-hull fitting; this is in turn glued to a 25 mm elbow. The flow of water is regulated by a 25 mm one-way ball valve. A 25 mm pipe is dry fitted to the valve and to a 25 mm ID hose for collection of larvae; in this way, a gentle outflow of water is obtained from the larval tank, minimizing any crushing of larvae.

The technical drawing diagram – 2/Pg13, shows, in detail, the equipment utilized for collection of larvae during water transfers. As larvae are culled at every water change, two sieves are placed one within the other; the smaller 20 cm diameter sieve is balanced inside the larger 25 cm diameter sieve, and is supported by a 15 mm transverse pipe, resting on top of the lower sieve. Sieves are kept in plastic non-toxic trays (used in the restaurant trade), and supported by a 2.5 cm high ring off the bottom; this set up allows collected larvae in both sieves to remain continuously submerged, and for those collected on the bottom sieve to avoid direct contact with the tray and subsequent crushing and damaging of shell. Care is taken that the top of the bottom sieve is above the tray level, so as to not lose any larvae during collection. In this way, water flowing from the larval tank passes through both sieves, where larvae are separated by size and collected; water remaining in the tray, overflows and is discarded without any loss of larvae. Water level in the tray and flow rate from the tank must be monitored through the entire draining process to ensure that the sieve does not become clogged with larvae and overflows; this would cause larval loss. For culling larvae, larger larvae are collected first in the 20 cm sieve (with larger mesh aperture) and smaller larvae are collected in the 25 cm bottom sieve (with smaller mesh aperture). The technical drawing photo – 4/Pg13 illustrates the set-up of trays and sieves for collection of larvae during a water change.