Chapter 6 Economic considerations: costs of set-up and labour requirements

6.1 SET-UP COSTS OF A MODULAR HATCHERY

The equipment and materials required for the set-up of the hatchery/nursery complex and for the carrying out of the rearing protocols are given in detail in Appendix 22. This list is given as an aid to assessing the needs for setting-up and operating a modular hatchery and assist in costing out such a hatchery.

In-depth economic studies have been conducted on other scallop species (Paquotte and Fleury, 1994; Dredge et al.2002), which provide the capacity for modelling. The intent here is to provide baseline information which can thereafter be used in modelling, if required.

For ease of understanding, the list provided has been divided into several sections. Firstly, equipment and materials required for each section of the complex is given with price at the time of publication of this document. It must be noted that all prices are given in US Dollars (USD). Although prices will vary among sites, this can provide a general estimate of the funds required. Additionally, a list of suppliers used for the construction of the Bermuda modular hatchery is given, and may be useful for construction of hatcheries in North and South American regions. Secondly, the list provides small equipment and materials required for conducting the protocols described in this manual. Once again, associated costs (at the time of publication) and suppliers are provided.

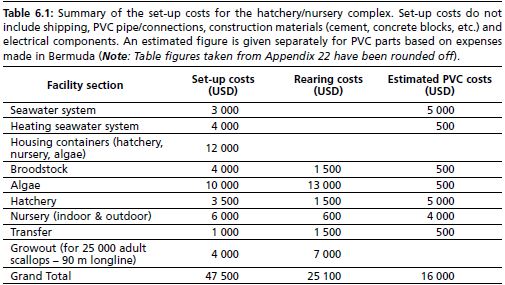

Set-up costs and rearing costs involved for this “portable” model hatchery are summarized in Table 6.1 below. earing costs refer to requirements for farming scallops as outlined in the protocols of this manual. The price of PVC pipe and parts required for the whole complex is estimated at the price purchased in Bermuda. It has to be kept in mind that Bermuda has a high cost of living and prices given here need to be adjusted to a given region.

The amount of PVC required can be estimated from the technical drawings. In total, in Bermuda, it is estimated that USD 16 000 is required for PVC parts. Set-up costs amount to USD 47 500 in Bermuda, and include all equipment outlined in Appendix 22 for set-up. Initial rearing costs amount to USD 25 100 and include all equipment outlined in Appendix 22 for rearing of scallops. The total cost for a turn-key modular hatchery, excluding labour costs, amounted to USD 88 600 in Bermuda. Yearly operating costs are not included here.

Table 6.1: Summary of the set-up costs for the hatchery/nursery complex. Set-up costs do not include shipping, PVC pipe/connections, construction materials (cement, concrete blocks, etc.) and electrical components. An estimated figure is given separately for PVC parts based on expenses made in Bermuda (Note: Table figures taken from Appendix 22 have been rounded off).

Note:

- Rearing costs for broodstock include materials for spawning procedure (Appendix 22). - Rearing costs for algae include materials for master and sub-culture, live & dry algae (Appendix 22).

- Rearing costs for hatchery include materials for construction of sieves and miscellaneous equipment (Appendix 22).

- Rearing costs for nursery include materials for construction of sieves for indoor and outdoor raceways (Appendix 22).

- Rearing costs for transfer include transfer materials (Appendix 22).

- Rearing costs for growout include growout materials (Appendix 22).

PVC costs for seawater include main seawater intake line, pump house, main supply to heating unit, algal unit and hatchery complex; as well as main drain pipe system. PVC parts for hatchery include main ambient and heated seawater line to all tanks and air line.