1.2 HATCHERY DESIGN CONSIDERATIONS

1.2.1 Introduction

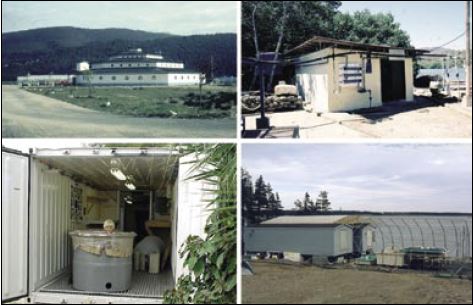

There is no rigid design for a bivalve hatchery. The layout of hatcheries varies from site to site, with species produced, geographic location, funds available, the target production species and personal preferences (Figure 3).

Some hatcheries are small and supply seed for their own bivalve on-growing culture operations. Others are large and may only produce seed for sale, or they may produce seed for their own operations and also an excess to sell to other growers. Hatcheries may or may not include a nursery component and some may only produce mature larvae for shipment elsewhere while others may grow and supply seed varying in size from 1 to 12 mm shell length. Much depends upon the nature, requirements and the level of sophistication of the growout operations that collectively make the customer base.

Figure 3: A selection of photographs of hatcheries depicting the variability in size and sophistication of construction that exists around the world. Clockwise from top left: Tinamenor S.A. (Pesues, Spain), Turpiolito hatchery, (Gulf of Cariaco, Venezuela), Bermuda Biological Station’s scallop hatchery based on insulated cargo containers and the SMS oyster hatchery (Point Pleasant, Nova Scotia, Canada).

Many hatcheries were built with little advance planning or forethought for possible future development. A hatchery was built to produce a required quantity of seed and when the initial objective was achieved a decision was made to expand and add extra capacity. The resulting facility is often neither efficient nor worker friendly. Other hatcheries were built to produce seed of a single species but other species are produced now and the resulting hatchery is somewhat inefficient in its new role.

Considerable time will be saved and many frustrations avoided if a hatchery is carefully planned before construction begins. Several considerations must be remembered when designing a hatchery and two are of great importance. Firstly, the hatchery operation must be worker friendly and efficient to make the operation as profitable as possible, and secondly, the need for future expansion must be kept in mind.

There are two basic parts to a bivalve hatchery, the salt water system and the physical plant.