3.4.4 Automated large-scale culture

So far discussion has centered on semi-continuous culture methods. Although less labour intensive than batch harvested systems, the manpower component in operating a daily harvesting schedule is still relatively high. As a consequence it is usual to decrease the harvesting rate to 48-h intervals.

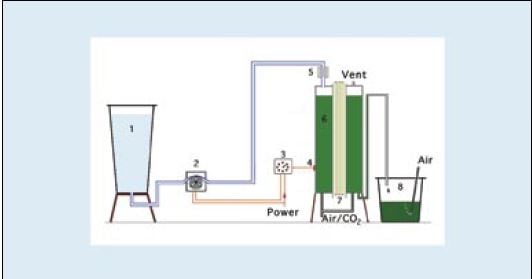

This is achieved by operating the cultures at a lower PHCD. Nevertheless, the point of maximum yield can be reached within the 48-h interval so that light limitation will influence overall productivity. The solution is to operate the cultures continuously, i.e. continuous harvesting. This solution is feasible using opto electronic control of cell density. A diagram of an automated system developed and used at the Fisheries Laboratory Conwy, UK is shown in Figure 30.

Figure 30: Schematic of a continuous (“turbidostat”) culture system (not drawn to scale). Key: 1, reservoir of seawater medium (200 l volume); 2, peristaltic pump; 3, resistance sensing relay (50 to 5 000 ohms); 4, light dependent resistor (ORP 12); 5, cartridge filter (0.45 ?m); 6, culture vessel (80 l volume); 7, six, 80 W fluorescent lamps; 8, collecting tank to receive the harvest (125 l volume).

The key component in this system is a Light Dependent Resistor (LDR) clamped onto the outer surface of a transparent culture vessel. Light falling on the LDR after penetrating the culture varies depending upon the density of cells in the culture. Internal illumination is used, as in the semi-continuous, large-scale systems previously described. As cell density increases the light transmittance through the culture decreases and this increases the resistance value of the LDR. This increase is detected by a Resistance Sensing Relay (RSR) which is set to activate a peristaltic pump when a certain pre-set resistance value is reached. The RSR is adjusted to operate at the light intensity at which cell division is at a maximum. When activated, the peristaltic pump supplies fresh medium to the culture vessel and this displaces an equal volume of the culture into a receiving container. As the culture in the vessel becomes increasingly diluted, the transmittance of light through the culture, detected by the LDR increases, the resistance of the LDR decreases, and the RSR switches off the peristaltic pump.

This apparatus is inexpensive to construct with modern electronics and is very effective in maintaining cultures at peak productivity. Yields from an automatic, 80 l system for Isochrysis galbana (Clone T-Iso) and Tetraselmis are similar to those from the larger, 200 l units operating semi-continuously. A maximum yield of Tetraselmis of about 100 l per day at 1 000 cells per ?l is achievable by operating the automatic system at about 2 000 cells per ?l. Yields of about 90 l per day at 10 000 cells per ?l have been obtained with lsochrysis operating at a culture density of 16 000 cells per ?l.

The principle of automatic operation is not new. Chemostats or turbidostats using external light sources for the production of microalgal species have previously been described. The Conwy system described above is an updated and more efficient version of the concept. Continuous culture systems based on either vertically or horizontally arranged, polyethylene bag units are commercially available.