6.1 INTRODUCTION

The word “spat” is an old English term applied to the early juvenile stage of bivalve development and is perhaps the most commonly used term applied to juveniles in hatcheries. It relates to bivalve larvae that have set and undergone metamorphosis.

Another frequently used term for early juveniles is “seed” and this word is used to describe juvenile products supplied by hatcheries to shellfish farmers.

The extent to which hatcheries are involved in growing spat beyond pediveliger stage larvae varies considerably and relates to the preferences of the growout industry. Provision of eyed, pediveliger Pacific oyster larvae for remote setting at oyster farms is common practice on the Pacific coast of North America. Hatcheries provide the mature larvae and the farmers themselves set them and grow the spat for seeding oyster beds or in suspended culture. Details of the methodology are given in 6.2.

In other parts of the world hatcheries set the larvae and grow the spat to a size that growers are comfortable to handle and grow. This may be when spat are 1 to 2 mm in shell length or often larger. The size that spat is supplied is largely dictated by the requirements and maturity of the growout industry. Hatcheries would prefer to deliver them at the smallest size possible because the economic implications of growing them further within closely controlled conditions are significant. It takes only a relatively small tank volume and a comparatively small quantity of algae to grow larvae and set a million spat but once they are set costs associated with growing them escalate rapidly.

Consider the requirements of 1 million oyster spat. At 1 mm shell length, individual live weight (shell and body) is approximately 0.3 mg. Clam and scallop spat are about 30% lighter than oyster spat for a given shell length within the size range grown in hatcheries. The biomass (total live weight) of one million oyster spat is therefore 0.3 kg. Growth rate of spat in closed seawater systems (systems without continuous water exchange) is biomass dependent. To ensure commercially acceptable (not maximum) growth rates, spat need to be grown at a maximum of 200 g live weight biomass per 1 000 l (0.2 kg per m3). This is the biomass at the beginning of a weekly period irrespective of the size spat are and allows for significant growth during the course of the week. Biomass is reduced at the end of a weekly period by distributing the spat at 0.2 kg per m3 in a greater tank volume – either more tanks of the same size or larger tank systems.

Growth rate decreases significantly as stock density per unit volume increases. At 0.4 kg per m3, for example, newly metamorphosed Manila clam spat will grow to only about 0.5 mm in a 6-week period compared to a mean shell length of 1.4 mm at 0.2 kg per m3. This is at the same temperature and with food ration calculated on the basis of biomass (section 6.4). It is not important to know the numbers of spat at this stage. Total live weight biomass is the criterion upon which food ration is based, i.e. the weight of shell, body and water contained between the shells. Section 6.3.5. describes protocols for grading and estimating seed.

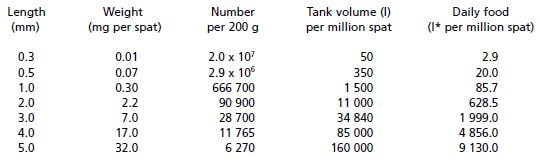

Returning to the example, one million 0.3 mg – 300 g in total – oyster spat will need a minimum culture tank volume of treated and heated seawater of 1 500 l. By the time they reach 5 mm shell length individual live weight has risen to approximately 32 mg. The biomass of one million 32 mg spat has increased to 32 kg and the volume of treated and heated water required to grow them is now 160 000 l (Table 14). Food requirements increase proportionately (section 6.4). For example, 1 million 0.3 mg spat require 17 g dry weight of algae per day, which is equivalent to 85 700 million cells of Tetraselmis suecica, or 85.7 l of harvested culture at 1 million cells per ml. At 5 mm shell length, food requirement for the same number of spat has risen to 9 130 l Tetraselmis at the same harvest cell density (Table 14). The 4 mm increase in shell length is associated with more than a 100-fold increase in biomass and the same increase in food is required. Clearly, there is a limit to the size hatcheries can grow the spat in terms of spatial requirements to accommodate them, the need to treat and heat seawater and the volumes of food required to feed them.

Table 14: Tank water volume and daily food requirements for bivalve spat of different sizes when grown at a biomass of 200 g live weight per 1 000 l (0.2 kg per m3). Data are for oysters but relate to other bivalves where clam and scallop spat are approximately 70% of the weight of oyster spat for a given shell length.

*Daily food requirement calculated as l of Tetraselmis at 1 x 106 cells per ml

Various solutions and approaches are adopted to overcome cost limitations to growing spat within the hatchery. These are described in section 6.3. Most commonly, spat are grown in closely controlled conditions to a size at which they will be retained by either a 1 or 1.5 mm mesh screen at 2 to 3 mm shell length. They are then transferred to outdoor nursery systems, which may be part of the hatchery operation or belong to a farmer or group of farmers. Or such nurseries may be part of a vertically integrated company operating a hatchery and producing seed for its own growout requirements. Outdoor nurseries are designed to protect small spat from predators while growing them at high density to a size at which they can be transferred to sea-based growout. Key features of outdoor nurseries are that they operate on the flow-through principle, utilizing natural phytoplankton productivity to provide the food supply (section 6.6). They may be land or sea-based and if they are located on land the source of seawater may be from artificially dug or natural ponds that can be emptied and re-filled from the sea. Measures are often taken to enhance algal productivity of the ponds by the application of fertilizers (see 3.4.6).

The following section deals with the special case of procedures for setting mature larvae at remote sites and growing them from the time they set to the time they begin growout to market size. Subsequent sections follow the various methods in common usage to grow recently set spat to suitable sizes within a hatchery until they are sold directly to farmers or transferred to land- or sea-based nursery systems.