6.3.3 Growing systems for unattached spat

Unattached spat (i.e. spat grown free of cultch – “cultchless”) are grown in large volume tanks equipped for recirculation – often with a gradual continuous exchange of water – or they are grown in open, flow-through systems. Whichever method is used depends on species and the size of spat. Smaller spat may be grown in recirculation systems until 1 or 2 mm in size and then be transferred to flow-through to grow to 3 or 4 mm before being sold or transferred to an outdoor nursery.

The spat growing area of a hatchery may contain a number of different growing systems for spat of different sizes and species. Most commonly the systems will utilize oblong concrete, fibreglass or lined or epoxy painted plywood tanks to use space as efficiently as possible. The large tanks that act as the reservoirs have drains plumbed directly into the hatchery’s main drain since large volumes of water will be discharged periodically.

Hatchery managers have their own preferences as to the best way to handle spat of the species they produce according to cost factors and what suits the particular requirements of the local industry. As with larval culture many different approaches are taken but there are a number of common factors that apply in the basic methodology.

Oysters are completely sedentary and clam and mussel spat are mostly so once they have settled and completed metamorphosis – scallop spat are the exception. Scallop spat retain the ability to detach their byssus attachment and briefly swim in the water column to find a different location to attach. Food needs to be carried to spat of any species in the water currents. How to manage them in a convenient way and the manner in which the water – as the carrier of food – is delivered to the spat become important considerations.

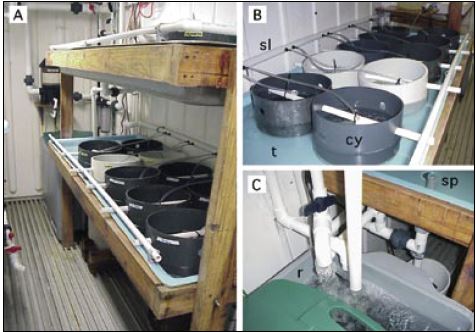

Figure 92: A closed tank system designed for holding scallop spat in cylinders with a downwelling flow of water. A – spat holding cylinders are held in shallow troughs (t) stacked one above the other. B – water flows into each cylinder (cy) through a flexible tube connected to the supply line (sl). C – water returns to the reservoir tank (r) via a stand-pipe (sp) fitted in each trough which maintain the water depth in the troughs. Water is pumped from the reservoir back to the troughs. Systems of this type are also suitable for clam spat.

Spat are almost always contained in mesh based trays or cylinders in a holding tank which, if not of sufficient volume itself, is connected with a large-volume reservoir tank. Containment of spat in trays or cylinders facilitates ease of management in cleaning and grading the animals. Water with algal food is circulated by electric pump or air-lift from the reservoir to the holding tank, passed by the spat and then returns to the reservoir. Examples suitable for growing scallop and clam spat have previously been given in Figures 87 and 88. Figure 92 shows the delivery of water to each of the cylinders in the holding tank by a flexible hose attached to nipples in the delivery pipe. Water flows in from above the water surface within the cylinder at a controlled rate, downwards passed the spat and out through the mesh base of the cylinder to be returned to the reservoir by a stand-pipe or an overflow which maintains the water level constant in the holding tank. This flow pattern is called downwelling. The other approach used for oysters and clams is to reverse the direction of flow so that it enters at the base of the cylinder (or tray), passes upwards through the bed of spat and is discharged at the top, from wich it flows back into the reservoir. This is referred to as an upwelling circulation. Both of these principles are illustrated in Figure 93.

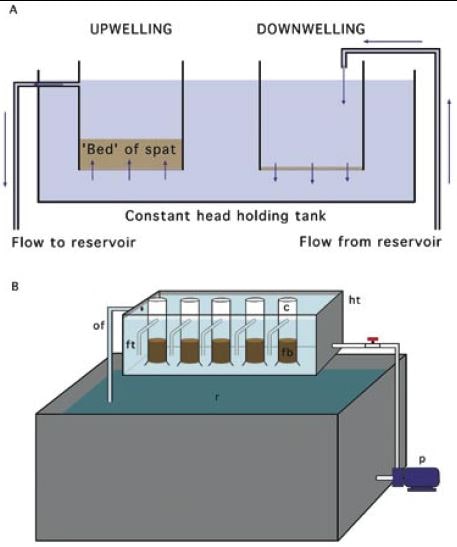

Figure 93:

A – diagram illustrating the difference in flow circulation in upwelling and downwelling spat systems. Arrows show the direction of water flow. Upwelling systems are used for oyster spat from set size upwards and for fully metamorphosed clams. Downwelling systems are used for clam pediveligers (until they have completely lost the ability to swim) and for scallops from the pediveliger stage onwards. Only rarely are upwellers used for scallops and then at a much lower biomass per unit area than for oysters and clams.

B – diagram of an upwelling tank system showing the reservoir (r) from which water is pumped (p) to a holding tank (ht) maintained at a constant water level (head) by an overflow pipe (of) through which excess water is discharged back to the reservoir. The holding tank contains a number of tall, narrow cylinders (c) with mesh bases in which the spat are held as a fluidized bed (fb). Holes are drilled in the holding tank below water level to take flexible tubes (ft) that interconnect with the cylinders. Thus, there is a head difference between the water level in the holding tank and the water level that can be maintained within the cylinders. Water flows through the mesh bases of the cylinders, up through the bed of spat and then back to the reservoir through the flexible tubes. The extent to which the spat bed is fluidized (i.e. the spat lifted by the flow) can be changed by altering flow rate.

It is quite common to use inverted, plastic soft drinks bottles of 1 to 3 l volume as upwelling cylinders. Instead of a mesh screen containing the spat, a ball or large marble is placed inside to cover the opening of the neck. This serves as a non-return valve. The flow of water from the bottom keeps the juveniles suspended in the water column inside the cylinder but if water pressure is lost the ball or marble seals off the neck so that no juveniles are lost. Discharge water from a series of upwelling bottles is passed over a screen to collect any juveniles that may accidentally float away.