6.3.7 Operating systems on flow-through

Tank systems of the various kinds described above are often operated with a partial exchange of water each day or on a continuous open flow. Partial or total flow-through systems are used for growing larger spat when maintaining a temperature higher than the ambient is not an important consideration, i.e. when ambient water temperature is sufficiently high to support good growth.

Two advantages of flow-through are a) the increased biomass of spat that can be held and grown in the spat holding tanks and b) spat can benefit from the natural or enhanced productivity of the exchange seawater. The diversity of algal species in the generally coarsely filtered exchange water more closely resembles natural conditions as spat are gradually acclimated in preparation for transfer to growout.

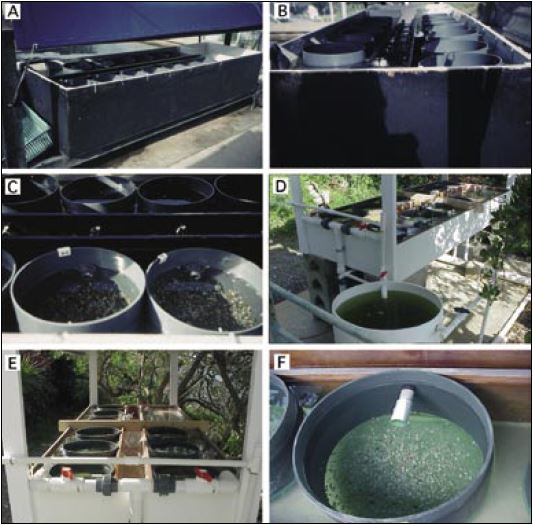

Figure 96: Upwelling tank units for larger size spat operating on flow-through. A, B and C – a system for growing clam spat at high density. This system is in circuit with a 90 m3 outdoor concrete reservoir in which naturally occurring algae is “bloomed” by adding nutrients.

Note the central collecting channel which carries the upwelling water flow from the cylinders back to the reservoir. This is a pumped system. D, E and F – a system for growing scallop spat at lower density. This unit is plumbed directly into the hatchery’s main seawater supply and is fed continuously from a reservoir containing diluted algal paste, which can be seen in D. Otherwise, the configuration of the system is similar to A with cylinders either side of a central water collecting channel.

It was pointed out in section 6.2.3 that the optimum biomass for growing spat in closed systems is 200 g per m3 of the total volume of the reservoir and spat holding tank combined. Consider the example of a 3 000 l tank unit given in section 6.2.4 in which 600 g live weight biomass of spat will grow at a satisfactory rate. When total tank volume is completely exchanged in the course of a 24-h period then the biomass can be approximately doubled. At this rate of water exchange – equivalent to 125 l per hour – and assuming that cultured algae is the principal food source, little food will be lost especially if it is added directly to the spat holding tank of the unit. The food ration will need to be doubled because the biomass of spat has been increased by a factor of two. At the higher spat density and the increased quantity of food, tank fouling with faeces and detritus is greater and needs to be taken into account during routine husbandry. The tank units may need to be drained and cleaned three times a week instead of twice.

Spat holding tanks operating on total flow-through are usually configured differently. Instead of being in circuit with an adjacent reservoir tank they are stand-alone units, each being plumbed directly to the seawater supply (Figure 96D). They may be located inside the hatchery or outdoors. Many hatcheries operating flow-through units plumb a water supply from outdoor shallow ponds or very large volume tanks located adjacent to the hatchery premises. They are used to bloom algae. Furthermore, the temperature of the water in these ponds will be elevated above ambient sea temperature by solar heat gain for much of the year, particularly in temperate latitudes (see section 6.6). Seawater discharged from the spat holding tanks is returned to the ponds. In this way algae is conserved.

In essence, flow-through units are little different to the concept of nursery culture, which is described in greater detail in section 6.6. Hatchery-based flow-through units tend to be used for spat in the smaller size grades and many hatcheries will also have a nursery for the further growth of larger seed in close proximity. Staff can thereby manage the entire production process from egg to larger seed with the hatchery infrastructure of equipment, laboratory space, etc., available in support.