6.5.5 Hatchery production

Before considering the nursery culture of spat output from the hatchery it is relevant to consider the process of hatchery production as an entity. When designing a new hatchery the various parts of the operation need to be assessed in relation to expectations in terms of the targeted output of seed.

For example, the larval facility may be capable of setting 100 million larvae per year, therefore the capacity to grow spat needs to be equally matched to handle that production to whatever size the market requires. Likewise, the algal unit needs to be designed to reliably produce the daily volume of the required food species to feed the broodstock and the maximum numbers of larvae and spat at the various stages in development which will be in production at any point in time.

These factors will vary from hatchery to hatchery according to the species to be cultured and the anticipated volume of sales.

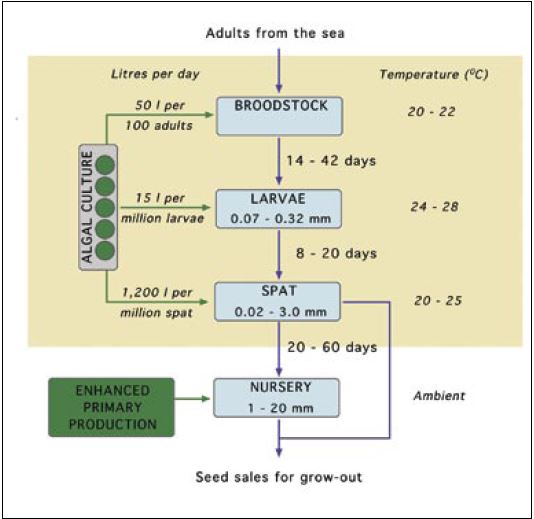

Figure 102: A summary flow diagram of the various aspects of hatchery production showing the temperature range and the daily food requirement per unit number of animals at each stage. This diagram is applicable to most warm water bivalve species.

As a general guide, a summary of the various facets of culture operation and requirements in terms of the temperature of the water and daily food rations is given in Figure 102. Also shown is a range in days that each stage in the production cycle will take which encompasses most warm water bivalve species. Food requirements have been calculated for the average size of larvae and spat that will be in culture on any given day when the hatchery is functioning at maximum capacity. It is assumed that spat will be grown to 3 mm shell length before sale or transfer to a nursery