2 Natural beach filter for seawater

SUITABLE BEACHES can be used as natural seawater filters for hatcheries. Some hatch eries draw water from perforated pipes protected by a 150 µm nylon screen buried approx imately 1 m deep in the beach. However, the screens are prone to damage and it is better to develop the beach itself as a filter. This annex describes a cheap filter probe made from plastic, which is derived from a stainless steel probe developed by a zoologist, the late George Cansdale. The following notes have been extracted from Suwannatous and New (1982). The system is easy and cheap to make and is described here in spite of some scep ticism that such simple systems are effective.

1. Basic requirements and capacity

Careful thought should be given to the location of the beach filter. A permeable beach is needed, with a depth of 2-3 m under a minimum of 30 cm water. Beaches of a wide range of types may be used, including sand, gravel, broken coral, shell, etc. The bulk of the sand grains should be between 0.5 mm and 5.0 mm but a great advantage of this system is that, during the development of the filter, excess fine sand is pumped out, leaving the larger grains in and around the filter probe; thus a precise sand specification is not needed. Uniformly fine sand, especially of wind-blown origin, is unsuitable on its own, but it can be graded up by adding coarse sand or gravel under and around the unit. If most grains are above 2 mm diameter, it helps to add fine sand on the surface around the unit during devel opment.

‘Fine sand’ is defined for the purposes of this annex as material up to 1 mm and ‘coarse sand’ from 2 mm to 5 mm, but these are not technical terms. A few stones in the beach of up to 50 mm do not prevent it being developed as a filter bed but larger stones will reduce the efficiency of the filter and should be cleared away (or a different site chosen). Sites with little or no sand are not suitable for natural beach wells. Those with soft mud cannot be used. Where the beach is rocky some people have found that excavating a large hole and filling it with sand from another site, into which the filter probe is inserted, is effective. However, this may be very difficult and costly to construct and maintain. If the hatchery site is not adjacent to a beach with a favourable structure for a beach well there are a number of choices, including choosing a better site, bringing seawater (or brine) from another location (this is essential for inland hatcheries anyway), or pumping raw seawater and treating it within the hatchery.

The equipment described in this annex can be installed in any suitable beach. When this system was developed the original probes were constructed of stainless steel, which is expensive. However, cheaper plastic pipes can be used, provided the probes are taken up and cleaned more frequently.

The capacity of the pump required to operate the filter probe and the jet probe (see section 3), and the correct pipe diameter, depends on the water requirements of the hatchery, as well as its elevation above sea level and the distance between the pump and the filter probe, and between the pump and the seawater holding tank in the hatchery. It is important to have no noticeable flow resistance at the maximum water flow required. Equipment should not be too large for the characteristics of the site and the amount of water required by the hatchery, because this will result in excessive capital costs. Conversely, buying equipment which is too small for the site is a waste of money. The choice of pipe size is discussed in detail in an FAO manual (FAO 1992b). As an example of pump capacity, a 3 HP, 1 440 RPM self-priming electric pump sucking water from a filter probe 35 m distant through a 10 cm flexible hose (adapted down to 5 cm near the pump) and delivering water through a 10 cm pipe to a hatchery above the highest high-water mark to a site 350 m distant is capable of pumping about 20 m3/hr of seawater.

2. Construction of the filter probe

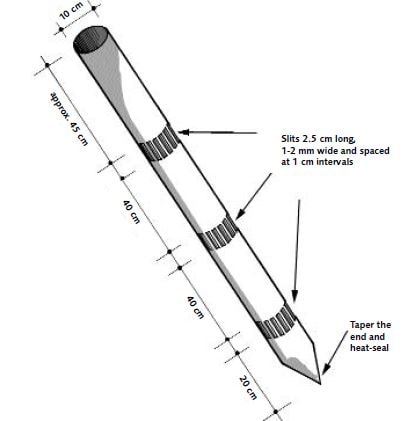

Soften the end of a 1.5 m piece of 10 cm diameter PVC pipe with heat, taper it to a point, and make sure that it is sealed. Then cut three sets of slits into it (Annex 2, Figure 1). The three sets of slits should be cut in rings. The lowest set should be 20 cm from the bottom of the pipe and the space between the three sets of rings should be 40 cm. From the upper set of slits to the top of the pipe should measure about 45 cm. Each ring of slits should be 2.5 cm long. The individual slits should be 1-2 mm wide and the spaces between them 1 cm wide. Flow can be increased by inserting more rows of slits but care must be taken not to weaken the pipe so much that it will fracture.

3. Installation and operation of the filter probe

Ideally, the filter probe should have at least 30 cm water above it at spring low tide. In very permeable sand on a level beach, a unit can sometimes be installed above low tide mark; it must be inserted as deep as possible. However, unless water has free access to it at all times, flow from probes inserted above low tide mark may be limited when the tide is out. Sea movements are daily and predictable, and a known factor in the suction head. Tidal pattern may vary widely: rise and fall may be from less than 2 m to over 15 m and the tide may recede anything from a few metres to over 500 m.

Dig a soft area in the inter-tidal zone of the beach, using a jet probe (use a pipe sim ilar to the filter probe but with a tapered open end and no slits) connected to the outlet side of the pump that will later be used for water extraction. The closer you can get to the low water mark the better, but you need to be able to get access to the probe for maintenance. Then fix the flexible hose to the top of the filter probe and push it into the softened sand to a depth of about 1.5 m. When it is in position, move the other end of the hose to the intake side of the pump and start extracting water, letting it flow to waste. The well will need ‘developing’, as explained below, before the water is of quality high enough to use in the hatchery. Once the well has been developed, connect the outlet side of the pump to the pipe supplying the seawater holding tank in the hatchery.

Where quality is critical, the water should be analysed and its quality monitored. In any case, the salinity of the water should be monitored during beach well site selection to make sure that it is high enough for the requirements of the hatchery (for freshwater prawn hatch eries, for example, it must always be higher than 12 ppt); in some areas the water sucked from a beach well may have been diluted to levels below this by freshwater run-off or beach springs.

ANNEX 2 FIGURE1

Good quality water can sometimes be obtained with simple beach filters; this figure illustrates a simple plastic beach filter probe

SOURCE: EMANUELA D’ANTONI

4. Developing the efficiency of the filter

The area of beach around the filter probe becomes the natural ‘beach filter’. Before it oper ates to the best efficiency it needs development. Thorough development is the key to suc cess and this section of the annex is most important.

When the filter probe is buried and the suction line has filled with water, this is then connected to the pump intake. Tight joints with washers are essential, for the smallest air leak delays priming and lowers efficiency. Underwater leaks may admit raw water; how ever, if these are very small, they soon block. The filter can be developed with a temporary pump close to the water. When the pump is fully primed, reduce its speed until it runs steadily. At first the water will be full of silt and organic matter as it cleans the bed. Depending on the site, the water will become clear in anything from a few to many min utes. Stop the pump and then re-start it; after a very short interval the water will become dirty but then it will soon clear. When this happens, stop and re-start the pump again. Releasing the partial vacuum disturbs the sand in and around the probe. This allows more fine material to be sucked out and gradually pushes back the perimeter of clean coarse sand, thus improving flow. This result is the main reason why the filter needs development so that it will work efficiently. Continue the alternate stopping and re-starting process until water no longer becomes dirty after restarting, and the pump is working to full capacity. The type of beach and the pump size determines how long this process will take. Where the beach has a lot of black organic matter, development is best spread over several days to allow this to decay aerobically, after which it is easily sucked out.

The water should now be crystal clear, free of all suspended matter and organisms down to about 1 micron (1 µm) or less. Where particularly high quality water is needed (i.e. for research work), the seawater should be pumped to waste for several hours daily for at least a week (while the biological filter is developing in the beach filter). The time needed for this varies with temperature and other factors.

Where adverse site conditions impede progress, the following procedures may be tried:

using a jet probe, dig the beach well in the area where the filter probe is to be insert ed, and let the current carry away much of the silt;

instead of just stopping the pump momentarily during development, release the suc tion completely, letting the water flow right back to the filter probe before re-start ing the pump;

interchange the intake and outlet hoses and reverse the water flow so that water is pumped through the filter probe into the beach for several minutes. Somebody needs to hold the probe in position during this process, to make sure that it does not become dislodged.

Small amounts of sand may be drawn through for some days, especially when pump ing is periodic, but this is sterile and can easily be settled in a primary tank or small baf fle chamber.

If the filter is only used intermittently it is good practice to pump some water to waste each time it is re-started; this need be for only a few minutes if the time since it was last used is only a day but should be about an hour if the filter has not been used for a week. Local experience will show how long water needs to be pumped to waste on each occasion.

5. Maintaining the efficiency of the filter

There is a tendency for the flow of water passing through any filter to gradually decrease, as the spaces between the filter bed particles become blocked. In marine sites tidal and wave movements generally keep the surface of the beach filter clear. If blocking does occur, this will only be in the top 1-3 cm, usually only the top 1 cm. If the flow from the filter becomes reduced, and this is not due to declining pump performance or other factors, this suggests that there is surface blocking. This can be cured in several ways, including:

stopping the pump and raking an area of about 5 m radius around the probe, work ing to a depth of about 5 cm, then pumping the water to waste and redeveloping the filter for as long as needed;

skimming off about 3 cm of sand from the surface and replacing it with new sand; forking the area over lightly and back-washing the filter by moving the suction hose to the pump outlet and drawing water through a spare hose. Somebody needs to make sure that the probe does not become displaced during this operation;

moving the filter probe to another area and developing a new beach filter. A firmly embedded filter probe can be quickly freed by changing over suction and delivery hoses at the pump and blowing back, after letting some air into the line.

A change in tidal pattern or a badly sited breakwater may cause a metre or more of sand to be removed from the beach, though this is unlikely near or below low tide mark. If the filter probe becomes exposed because of this type of problem, it must be re-installed and re-developed.