OYSTER CULTURE PROCEDURES

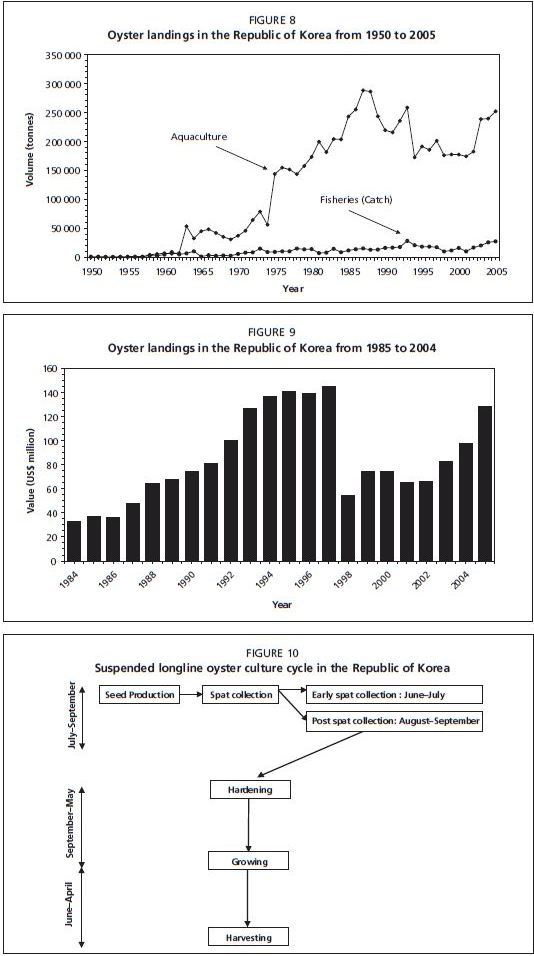

The process of oyster aquaculture includes: 1) seed production (collection of natural spat or artificial spat production from hatchery); 2) hardening (i.e. stunting); 3) grow out; and 4) harvest (Figure 10).

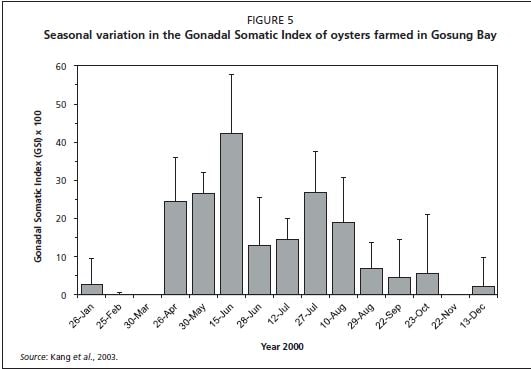

Figure 5

Seasonal variation in the Gonadal Somatic Index of oysters farmed in Gosung Bay

Source: Kang et al., 2003.

Seed production phase

Obtaining a sufficient quantity of healthy larvae is essential to support successful oyster production. The Korean oyster industry mainly relies on the collection of natural spat. According to the Korean Oyster Longline Culture Cooperative, natural spat supply 90 percent of the national oyster seed demand, while hatchery-produced seed provide the remaining 10 percent. As shown in Figure 3, mature oysters spawn as early as mid-May and continue to do so until the end of September. Depending on key environmental parameters, such as water temperature, salinity and food availability, the larvae settle 10–20 days after fertilization.

To ensure the collection of a large number of spat, the abundance and development stage of the larvae in the water column are routinely monitored by the regional marine extension services. The monitoring data, including information on the expected maximum oyster spat-fall period, are then conveyed to the oyster growers. Furthermore, an “oyster larval-forecasting” newsletter is posted on specific websites on a weekly basis from mid-May to end August. In the meantime, oyster growers prepare the spat collectors and place them at sea when the abundance of the larvae is at its highest value.

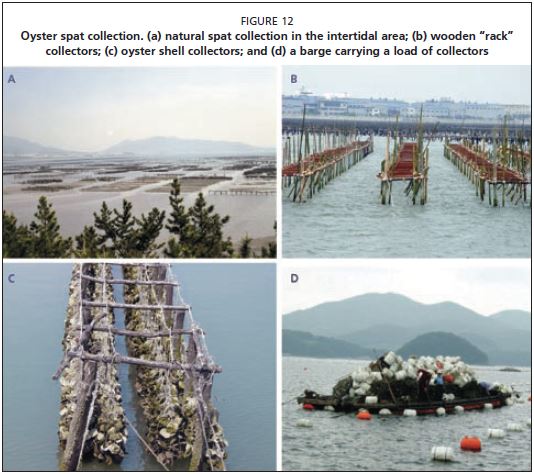

Adult oyster or scallop shells are used as substrate (i.e. cultch) for the larvae to settle on. A spat collector is prepared by first piercing a hole in the middle of the dead oyster or scallop shell and then stringing 50–60 pieces on a 1.5–2 m plastic line (Figure 11). Oyster spat are traditionally collected from the intertidal zone by suspending the collectors on wooden racks which are periodically exposed for 2–3 hours during low tide (Figure 12). Spat can also be collected from subtidal areas by submerging the collectors from the boat. The optimal spat density for each cultch (i.e. oyster or scallop shell) is considered to be 30 spat per single oyster shell or 40–50 spat for each scallop shell.

To ensure the availability of the required volume of seed, both “early spat” collection (June–July) and “late spat” collection (August–September) are targeted by the industry. In 2005, the early spat collection effort started in early June and continued till the end of June, during which time 5.5 million oyster seed collectors were utilized to collect the spat. In 2005, a total of 14.1 million oyster spat collectors were used indicating that spat settlement was more intense during late summer (late spat period).

Oyster capture-based aquaculture in the Republic of Korea 277

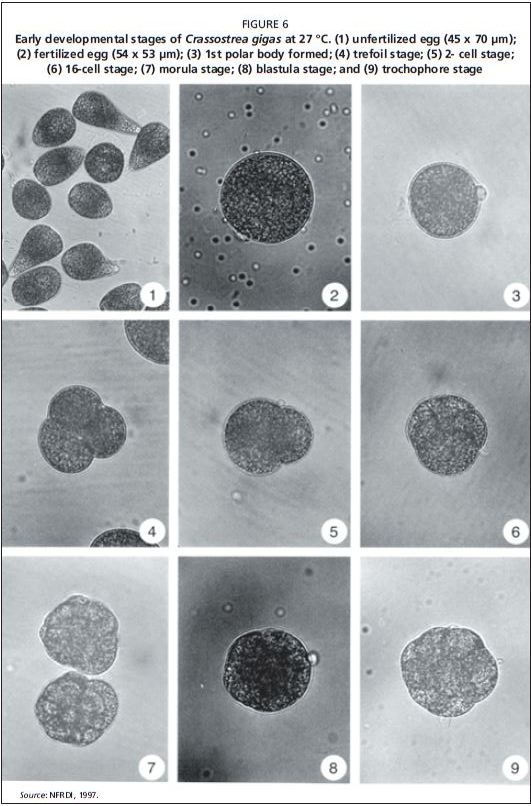

Figure 6

Early developmental stages of Crassostrea gigas at 27 °C. (1) unfertilized egg (45 x 70 ?m); (2) fertilized egg (54 x 53 ?m); (3) 1st polar body formed; (4) trefoil stage; (5) 2- cell stage; (6) 16-cell stage; (7) morula stage; (8) blastula stage; and (9) trochophore stage

Source: NFRDI, 1997.

More recently oyster seeds have also been used from private hatcheries located on the south coast. The conditioning of broodstock allows hatchery operators to start seed production as early as February and complete the production before the natural spat collection begins. In 2005, approximately 3 percent of the oyster spat demand was supplied from private hatcheries. Spat are also imported from Japan and the United States of America. For example, in 1997 almost 16 percent of the national spat demand was supplied from hatcheries in the United States of America due to poor natural harvest that supplied only 70 percent of the industry requirement (Han, 2005).

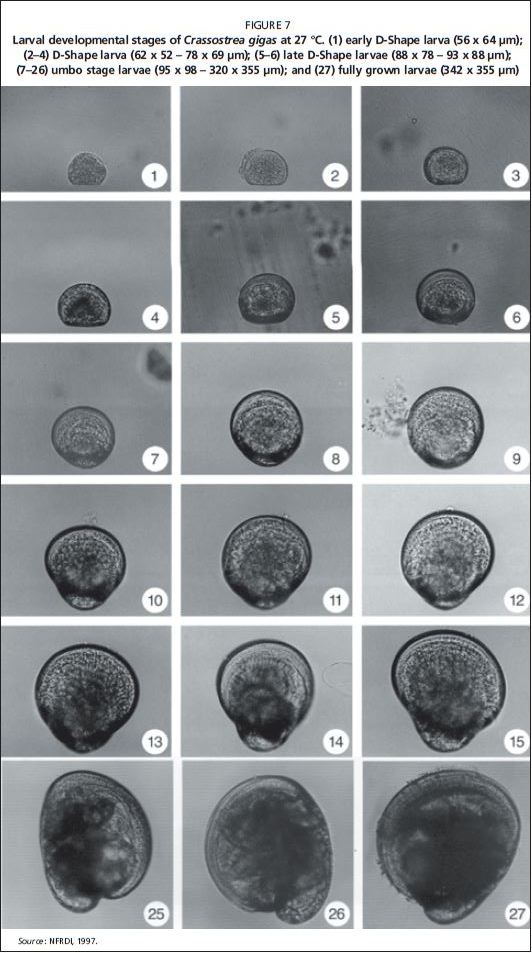

Figure 7

Larval developmental stages of Crassostrea gigas at 27 °C. (1) early D-Shape larva (56 x 64 ?m); (2–4) D-Shape larva (62 x 52 – 78 x 69 ?m); (5–6) late D-Shape larvae (88 x 78 – 93 x 88 ?m); (7–26) umbo stage larvae (95 x 98 – 320 x 355 ?m); and (27) fully grown larvae (342 x 355 ?m)

Source: NFRDI, 1997.

Figure 8

Oyster landings in the Republic of Korea from 1950 to 2005

Figure 9

Oyster landings in the Republic of Korea from 1985 to 2004

Figure 10

Suspended longline oyster culture cycle in the Republic of Korea

Figure 11

Assembling of oyster spat collectors using a plastic line and oyster shells

Figure 12

Oyster spat collection. (a) natural spat collection in the intertidal area; (b) wooden “rack” collectors; (c) oyster shell collectors; and (d) a barge carrying a load of collectors

Hardening phase

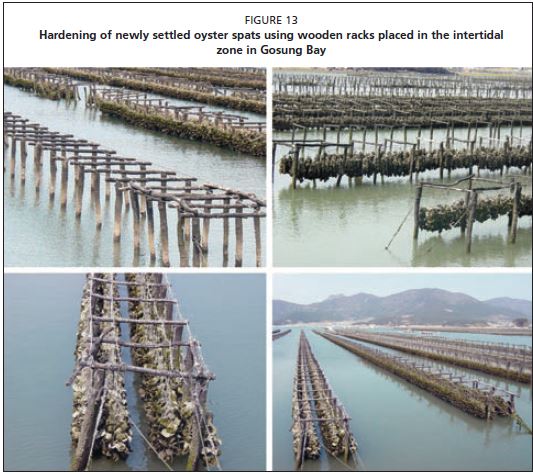

Ten days after settlement, the oysters attached to the collectors are transferred to the hardening ground, or directly to the longline culture system for grow-out. Since hardened oysters have a better survival rate, the oyster growers routinely undertake this culture phase. Hardening the seed oysters takes place in the intertidal zone where the area is exposed for 6–8 hours during the tidal cycle. As shown in Figure 13, a series of wooden racks are built in the intertidal area from where the collectors are suspended. The hardening period begins in September and continues until the following April, during which the seeds are periodically exposed to the atmosphere during low tide to eliminate unhealthy and weak individuals. In May, the hardened seed oysters reach

Figure 13

Hardening of newly settled oyster spats using wooden racks placed in the intertidal zone in Gosung Bay

1–1.5 cm in shell height and are ready for grow-out. At the end of the hardening period, the number of spat initially settled on the shell surface (40–60 spat/shell) drops to 20–30/shell. The stunted oyster seeds tend to grow faster and show a high survival rate during grow-out.

Grow-out phase

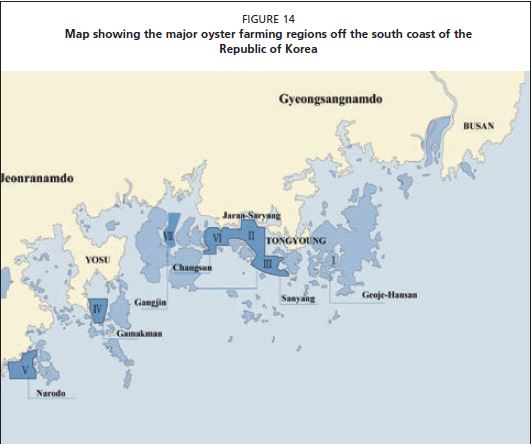

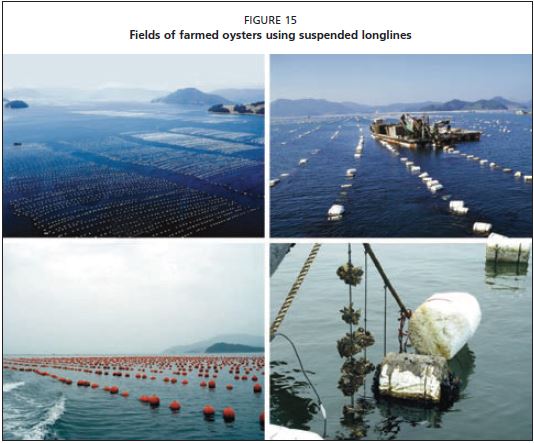

Approximately 90 percent of the Korean oysters come from farms located in small bays and off islands along the south coast. Figure 14 shows the location of the 7 major oyster culture sites in the south, where 258 oyster leases utilize approximately 1 983 hectares of sea surface for grow-out activities. These areas are protected, shallow (5–20 m deep) and have a high primary productivity. The oyster farms along the south coast exclusively use the longline culture system. The oyster stings are suspended on a submerged longline which is supported by numerous buoys (Figure 15).

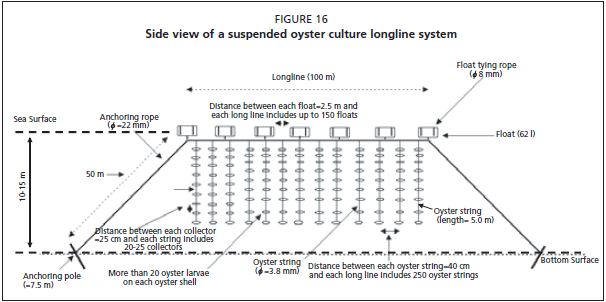

In May, the hardened seed oysters collected from the previous summer reach 1–1.5 cm in shell height. For grow-out, the hardened seed oysters attached on the clutches and suspended on the hardening racks are harvested and the seed strings are disassembled for longline culture. Using a plastic wire (o=3.8 mm) each cultch (i.e. oyster or scallop shells containing the hardened seed oysters) is strung on the wire at 20 cm intervals. The 5 m long oyster grow-out string may include 20–25 cultch.

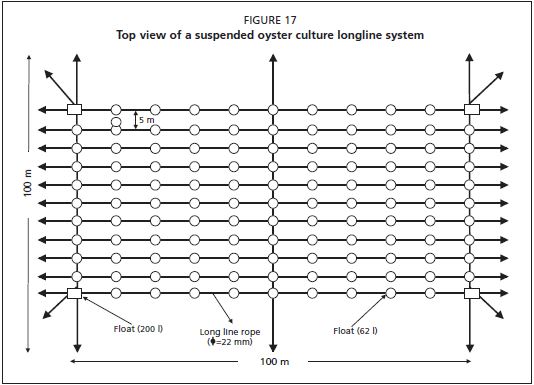

Figures 16 and 17 illustrate a schematic view of a longline oyster grow-out facility. Each longline is a 100 m long rope (o=22 mm) kept afloat by as much as 150 buoys (62 litres). On each longline, 200–250 strings of the hardened seed oysters are suspended. The grow-out for the seed oysters lasts for 6–10 months before harvest. During the grow-out period, the oyster seeds grow to 8–12 cm in shell height or 9–15 g in tissue wet weight (Han, 2005).

Figure 14

Map showing the major oyster farming regions off the south coast of the Republic of Korea

Figure 15

Fields of farmed oysters using suspended longlines

Figure 16

Side view of a suspended oyster culture longline system

Figure 17

Top view of a suspended oyster culture longline system5 m

Harvest

On the south coast, harvesting oysters from the longline begin as early as in September and the harvesting continues until the following April. The oyster strings suspended from the longline are lifted onto a work boat with the use of a winch installed on the side of the vessel. The oyster strings are then cut on the deck and dumped into plastic containers and sent to the local shucking factory (Figure 18). After several freshwater washing cycles the oysters are shucked and the flesh washed again with sterilized seawater before it is sorted by size for sale and further processing (Figure 19).