FISH TRANSPORT AND STOCKING

Transfer of live fish is required in order to transport the juveniles from the hatchery to the farm jetty and then from the jetty to the cage site for final stocking. Depending on the number and size of the fingerlings, fish may be delivered to the farm in transport tanks or in plastic bags filled with water and oxygen. This can be a delicate time for the fish, and great caution should be used to prevent unnecessary stress and mortality.

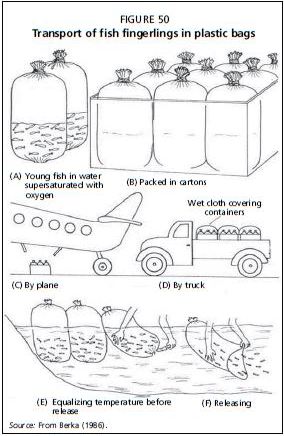

Plastic bags

This transport option is preferable for small numbers and/or small sizes of fish. If the fish are smaller than 1 g each, the final stocking into the cage must be delayed. It is not recommended to stock fish smaller than 1-2 g into the cages because the cage environment is not suitable for very small fish. Feeding cannot be correctly controlled; strong currents may stress the young fish, leading to high mortality. Moreover, predators may kill or injure a larger number of fish, and the counting of mortalities is more difficult with smaller fish.

Therefore, fish of about 1-2 g should first be held for a period of pre-growout, in a proper land-based nursery facility equipped with tanks, water inflow, aeration system, outflow depuration system and a water heater/ chiller system. Fingerlings transported in plastic bags (Figure 50) must be carefully acclimatized before they can be released into either cages or tanks. Plastic bags must be left floating in the new water to equalize the temperature. Then, the bags must be opened so that the internal and external water will slowly mix together. As the water exchange increases, the fish will become

fully acclimatized, and therefore can be released into the cage or tank.

If the juvenile fish are large enough to be stocked directly into cages, they can also be delivered in transport tanks (usually tanks installed on specialized flat-bed trucks). Different methods may be used for transferring the fingerlings to the cage site, including using a towed transport cage or a boat equipped with tanks.

Cage towing

The cage that is to be stocked is detached from the mooring system and then towed to a nearby jetty. At the jetty, the juveniles are transferred from the truck into the cage. The cage is then towed back to the site and moored in its final position.

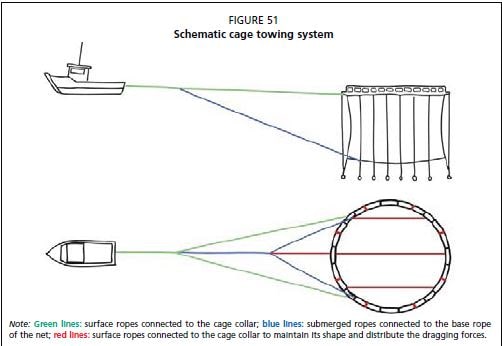

If a cage is to be towed, the following actions must be considered:

Check the site where the jetty is located. Carry out an underwater survey to verify its depth and the presence of rocks or obstructions that could damage the net.

• Reduce the net depth ("shallow-up" the net) and the length of the sinkers in accordance with the water depth in front of the jetty.

• Increase the weight of the sinkers on the up-current side (front, or leading edge) of the cage.

? Attach two or three additional tow lines, fixed onto the sinkers on the up-current or front side of the cage, which can help reduce net deformation and help maintain the available volume inside the cage (Figure 51).

Transport the fingerlings at a slow speed. A speed through the water of 1-2 knots is recommended. Consider currents.

Regularly check the fingerlings while towing them. At regular intervals, a diver should check that the juveniles are not becoming exhausted or being pressed back against the down-current (back) side of the net by the current. This would indicate that the boat is towing the cage too rapidly.

Take into consideration that, in case of current or in case of large cages, the drag force of the cage net could be very strong and the vessel may have not enough power to tow the cage, therefore the use of large vessels with enough horse power is recommended to execute this kind of operation.

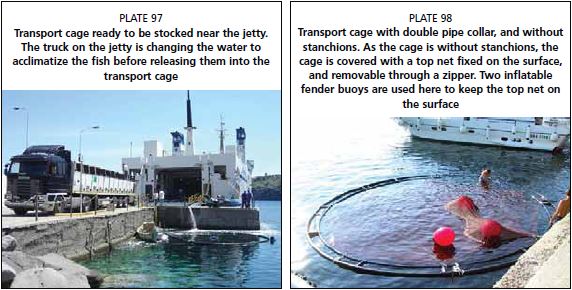

A smaller transport cage (Plate 97) may be used instead of a large grow-out cage. This would avoid having to detach the large cage from the grid. Moreover, a smaller transport cage is lighter and easier to manoeuvre, does not require a fixed mooring point, and can be easily stored away on land when not in use. However, if a transport cage is used, the fingerlings will need to be transferred into the grow-out cage at the farm site. This transfer procedure will depend on the design of the transport cage. Often, the most convenient method is to use a transport cage similar to that shown in Plate 98. This cage has no stanchions and has a lid that is closed with a zip. This allows the cage to be pushed/pulled under the collar of the grow-out cage. Once placed inside the net, fish can be readily released, and the transport cage can then be easily lifted out

of the grow-out cage by the boat's crane. To enable this, the grow-out cage must be prepared by lowering the top of the net under the water and removing some of the sinkers from the side where the transport cage will be introduced.

If a cage with stanchions is going to be used as the transport cage, then a different procedure should be followed:

Fasten the two cage collars together with rope.

? Unfasten a few metres of the grow-out cage net from the handrail and from the collar.

Unfasten a few metres of the transport cage net.

Join the top rope of the grow-out cage net to the top rope of the transport cage's net underwater (under the cage collars) using plastic cable ties.

The two nets are therefore joined together underneath the two cage collars, and a passage is available for transferring the fish by swimming them from one pen to the other.

Slowly lift the transport net by hand, or by using the crane, reducing the volume inside the net and forcing the juveniles to swim across into the grow-out net.

Fish transport tanks

Fish transport tanks should be equipped with an air diffusion system, valves for water inflow and outflow, and a large sluice door near the bottom. The tank should be insulated depending on the environmental conditions. A wide range of models is available on the market, but it is also possible to construct one by using large plastic tanks for potable water (such as those used as domestic water reservoirs for houses). On the large lower sluice gate, a special slide can be fixed for easy release of the fish. A plastic flexible tube can also be fixed onto this slide.

A boat equipped with fish transport tanks also needs to be equipped with:

Oxygen: It is possible to use oxygen cylinders from oxyacetylene cutting torches or those used for medical purposes. The number and size of the cylinders should be considered in relation to the number of tanks to be served, air diffuser efficiency, distance to the cage site, the temperature of the water, and specific species requirements.

• Water pump: Water will be needed if the transport tanks are equipped with open water circulation systems, to flush out the last fish of the batch, and to clean and refill the tanks if more than one batch will need to be transported in the same day. Oxygen meter: A hand-held oxygen meter will be needed. This should also incorporate a thermometer.

? Oxygen pressure regulator.

The maximum loading capacity of the boat will be a limiting factor because of the weight of the water in the transport tanks. The number and volume of the tanks carried on the boat is a key factor in optimizing transport operations. If a truck has been loaded with fish at a density (biomass per cubic metre) suitable for road transport lasting one or more days, the density of the transported fish on board the vessel may be doubled or even trebled, given that, during this operation, the water in the transport tank is renewed (it is not the same water as in the truck) and transportation to the cage takes a few hours or minutes.

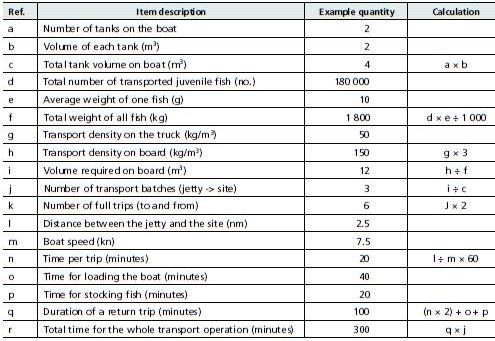

Table 34 provides an example of the calculations that need to be considered when transporting the juveniles to the cages, using a boat with transportation tanks, including number of trips, time required for transporting each batch, and time required for the overall operation. In the example provided (see Table 34), the density of the transported fish in the tanks on board the boat is three times the density of the fish in the tanks on the truck.

TABLE 34

Example of calculations for fish fingerling transport to the farm cages

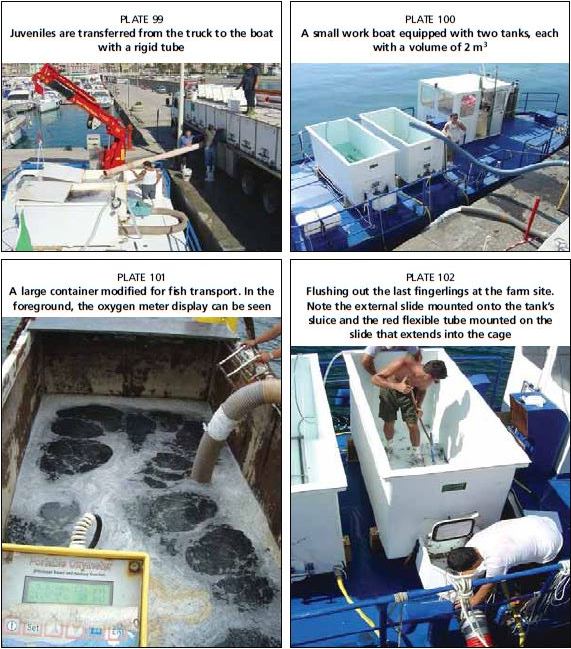

Operations for fish transfer by boat from the jetty to the cage site:

Secure all the tank openings..

Regularly check the levels of dissolved oxygen.

If DO decreases below the safety level (< 2-3 ppm) increase the oxygen pressure in the system (Plate 101).

Operations for fish release into the grow-out pen:

Securely moor the boat onto the cage collar or handrail.

• Install the tank slide, and place the flexible end of the transfer pipe into the cage. Lower the water level in the transfer tank, using the outflow valve.

When the water level is about one-third of the tank's total volume, open the tank sluice and flush out all the fish. A broom may be used to push the last remaining. fish out of the tank (see Plate 102).

At the end of the transport operation, always perform a dive check to verify mortality rates, to remove dead fish and to verify that the net is not damaged.

Operations for fish transfer by boat from the jetty to the cage site:

Secure all the tank openings..

Regularly check the levels of dissolved oxygen.

If DO decreases below the safety level (< 2-3 ppm) increase the oxygen pressure in the system (Plate 101).

Operations for fish release into the grow-out pen:

Securely moor the boat onto the cage collar or handrail.

• Install the tank slide, and place the flexible end of the transfer pipe into the cage. Lower the water level in the transfer tank, using the outflow valve.

When the water level is about one-third of the tank's total volume, open the tank sluice and flush out all the fish. A broom may be used to push the last remaining. fish out of the tank (see Plate 102).

At the end of the transport operation, always perform a dive check to verify mortality rates, to remove dead fish and to verify that the net is not damaged.